Welcome to The Gigacasting Newsletter

New here? Subscribe

New Patent Unveils How Tesla Can Rely Solely On Recycled Aluminum For Gigacasting Production

I’ve often talked about Tesla’s efforts to introduce a large amount of recycled aluminum from different sources into its Gigacasting process.

In this image captured by Joe Tegtmeyer you can see the different sources for Tesla’s secondary aluminum. This recycling plant is integrated right into Tesla’s Gigacasting shop.

The recycling facility at Tesla HQ in Austin, TX

This new patent published on December 18th describes Tesla’s Gigacasting alloy and the process to obtain the desired yield strength and ductility from a wide array of secondary aluminum sources.

ALUMINUM ALLOY COMPOSITION UTILIZING SCRAP METAL, AND METHODS THEREOF

Scrap aluminum, abundant from recycled sources, often contains impurities like iron (Fe), copper (Cu), and zinc (Zn) that can degrade performance, forming brittle phases that reduce ductility or cause casting defects.

This patent proposes a solution: Forming an alloy that can use at least 30% scrap aluminum (and potentially much higher, up to nearly 100%) by intelligently managing these impurities through targeted additives and two empirical metrics, the Hard Factor (HF) and Advanced Sludge Factor (ASF).

The solution involves a sophisticated chemical balancing act. Rather than expensively purifying this scrap, they measure the impurities in the melt and introduce specific "performance improving additives" such as manganese, magnesium, vanadium, strontium, and silicon.

The core alloy composition is tailored for the production of high strength large castings which don’t require heat treatment:

Silicon (Si): 6.5–8.5%

Manganese (Mn): 0.25–0.7%

Magnesium (Mg): 0.25–0.5%

Iron (Fe): ≤0.6%

Copper (Cu): ≤0.3%

Zinc (Zn): ≤0.35%

Titanium (Ti): ≤0.1%

Impurities: ≤0.3% total

Aluminum: remain

The resulting as-cast alloy delivers:

Yield strength: 110–190 MPa

Ductility (bend angle): 15–32°

High α-Al volume fraction: 85–99%

Limited brittle AlFeSi phases: ≤6%

These properties make it suitable for crash-critical structural parts, like underbody Gigacastings offering performance comparable to premium alloys but with greater sustainability.

Hard Factor and Advanced Sludge Factor

The Hard Factor is an empirical metric introduced to predict and control the balance between strength and ductility by controlling the use of performance improving additives. HF for an aluminum alloy may be adjusted by additions of Mg, Cu, and Zn, according to the empirical equation below.

- Hard Factor (HF) = (3 × Mg%) + (2 × Cu%) + Zn%

The Advanced Sludge Factor formulation can be used to reduce the risk of sludge formation within the melt furnace and to predict a volume fraction of AlFeSi phases that may be detrimental to ductility in a cast aluminum alloy product. It can also be used to ensure that the elemental content does not drift too low of a threshold which may negatively impact castability such as die solder and/or erosion.

The ASF can be adjusted according to the equation below.

- Advanced Sludge Factor (ASF) = Fe% + (2 × Mn%) + (3 × sum of V, Cr, Co, Ni, Mo%)

This technology enables "closed-loop" recycling for high-performance applications, reducing reliance on primary aluminum, which is energy-intensive to produce. It counters impurity buildup in scrap streams, potentially lowering costs and emissions while supporting the growing demand for lightweight, strong materials in electric vehicles.

If you would like to deep dive into this patent and all of its details you can read it from the source: patentscope.wipo.int

FAW Ramps Up Magnesium Parts Production

According to FAW Casting & Forging, 1,100 samples of independently developed magnesium alloy thixomolded end plates from its Casting & Forging R&D Institute have recently passed batch installation verification and enabled small-batch supply utilizing a dual cavity mold.

FAW noted that the semi-solid process significantly reduces defects such as shrinkage porosity compared to traditional casting methods, thereby helping to ensure better mechanical properties and thinner walls.

FAW has installed 850 ton and 3,600 ton magnesium thixomolding machines with the goal of developing structural magnesium components for its vehicles, including cross car beams, seat frames, body in white components, shock towers, touchscreen frames, etc.

First batch of battery end plates

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

American Magnesium Production

Article by Chemical & Engineering News

Two magnesium start-ups, Magrathea Metals and Tidal Metals, are making plans to start production of the metal in the US. The US Departments of Defense, Interior, and Energy all list magnesium as critical because its alloys are lightweight and strong.

Magrathea is forming a joint venture in Arkansas with the chemical maker Tetra Technologies, which is building a plant that will convert brine into bromine chemicals. Plans for the site include a scaled-up version of Magrathea’s complete process, which the firm started running at pilot scale in California earlier this year.

In addition to its technology, Magrathea brings to the partnership a $19.6 million commitment it won last year from the Defense Department to support construction of a commercial-scale plant using the firm’s technology.

Magrathea CEO and cofounder Alex Grant says the US uses about 100,000 metric tons (t) per year of magnesium at a market price of around $7,500 per metric ton. Globally, about 85% of the metal comes from China.

News reports about Magrathea have focused on the firm’s use of electrolysis to reduce magnesium salts to metal, but Grant says the firm’s special sauce is really its method of removing water, oxides, and hydroxide ions from magnesium chloride. Magrathea is cagey about the technical details but says its facility will cost 50% less per metric ton of capacity than competing approaches. Patent filings from the firm describe a molten salt system that uses a small amount of magnesium metal to convert MgClOH to the desired MgCl2, which becomes part of the melt, and MgO, which settles out as a solid.

Once Magrathea obtains dry, pure MgCl2, its process is similar to what US Magnesium had used since the 1970s and what Dow, starting from seawater, used in Texas from 1941 until 1998. Molten MgCl2 flows into an electrochemical cell that separates the salt into elemental magnesium and chlorine gas. Chinese producers mainly use the thermochemical Pidgeon process, in which ferrosilicon reduces magnesium-rich dolomite ore.

Meanwhile, Tidal is commercializing a related process that will make magnesium metal from seawater or desalination brine. The firm raised $8.5 million in seed funding last year and just announced that it has found an outlet for its chlorine secondary product. The distributor Alexander Chemical has agreed to package, market, and distribute chlorine from a future Tidal plant. The offtake plan is important, the firm says, because electrochemical magnesium production yields 3 t of chlorine for every 1 t of metal.

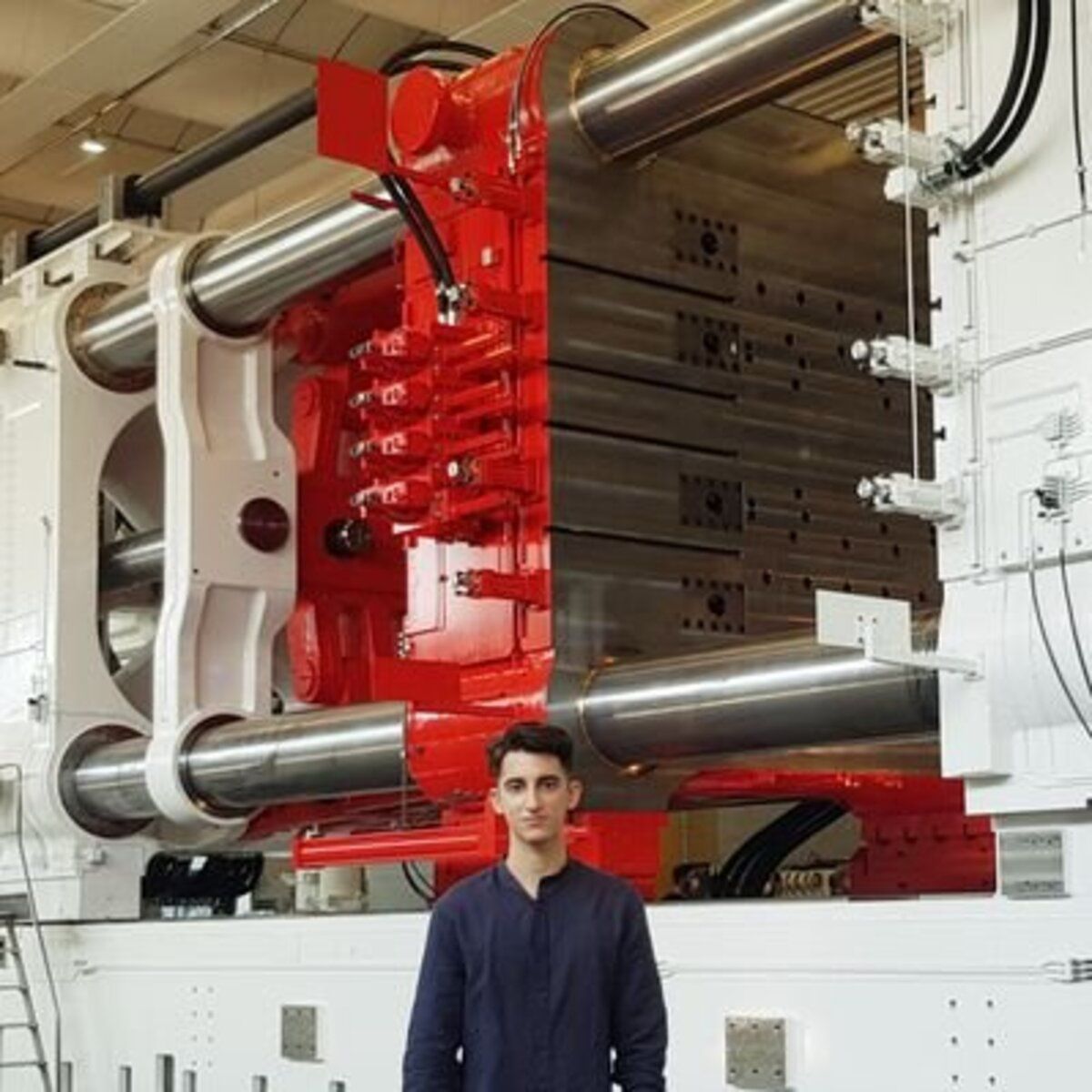

Volvo’s First 9,000 ton Gigacasting Machine In New Plant

This is Volvo's 5th Gigacasting capable machine installed worldwide.

The plant in Kosice, Slovakia is a newly built factory which will produce Polestar and Volvo electric vehicles starting from 2027. The first model to be produced at the factory will be the Polestar 7.

Source: Volvo Kosice on LinkedIn

More Magnesium Thixomolding Equipment Installed In China

Bole Machinery completed the delivery of a new 2,000 ton magnesium Thixomolding machine to the customer plant. According to Bole CTO, Timo Günzel, the dismantling of the MTX 2000D -135 S Thixomolding machine at Bole’s Ningbo plant and installation at the customer plant took less then two weeks.

MTX 2000D

Tesla Ramping Up Casting Production

With mass production scheduled for May 2026, Tesla is making trials and ramping up the production of die casting components for the Tesla Cybercab.

This new part ramping up is not an underbody Gigacasting but still a very large die casted part which is likely an upper body structural component.

I previously reported about details of the Tesla Cybercab and the unboxed manufacturing process in issue 45 of The Gigacasting Newsletter.

First high resolution images of Tesla’s Cybercab new upper body castings

2025 has been an important year for the Gigacasting industry, it marked 5 years after the first Tesla Model Y with Gigacasting technology entered the market.

In 2025 a record number of models in China adopted the technology and Western industry giants, like Volkswagen and Ford announced they are moving in this direction.

2026 is going to be an even more important year with the first European and Asian (non-Chinese) OEMs introducing Gigacastings on the market.

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: