Welcome to The Gigacasting Newsletter

New here? Subscribe

First Look At The Unboxed Manufacturing Process

We now have the first high resolution images and a short video of the front and rear sub-assembly sections of Tesla’s unboxed process.

The Front

Tesla Cybercab front sub-assembly. Front Gigacasting highlighted in yellow

From the video released during Tesla’s shareholder meeting, we can see the main front sub-assembly (built on the Front Gigacasting) being lowered down to mate to the other components, such as the steer by wire, heat management system, suspensions, etc...

The Rear

Left: Rear sub-assembly. Right: Rear Gigacasting

The rear sub-assembly of the Tesla Cybercab appears to be a hybrid body design which incorporates two (at least) large aluminum die casted components and stamped panels.

Notably, the large underbody Gigacasting forms the base of the entire structure while the newly spotted C-shaped casting forms the upper frame of the rear sub-assembly.

New C-shaped casting spotted

Tesla's "Unboxed" process is a manufacturing technique for electric vehicles that replaces the traditional linear assembly line, where vehicles move sequentially through stations for part additions, with a modular approach.

Instead, key sections of the car (such as the front, rear, battery pack, and side panels) are assembled in parallel sub-lines, mostly around the Gigacastings, as independent modules then integrated in a final assembly stage.

Why is this important?

This method aims to reduce production costs, shrink factory footprints by 40%, and accelerate output. Elon Musk also claimed the cycle time for this production line will be under 10 seconds. Toyota, GAC and Ford announced their own versions of the "Unboxed Process" while other European OEMs are also studying similar solutions.

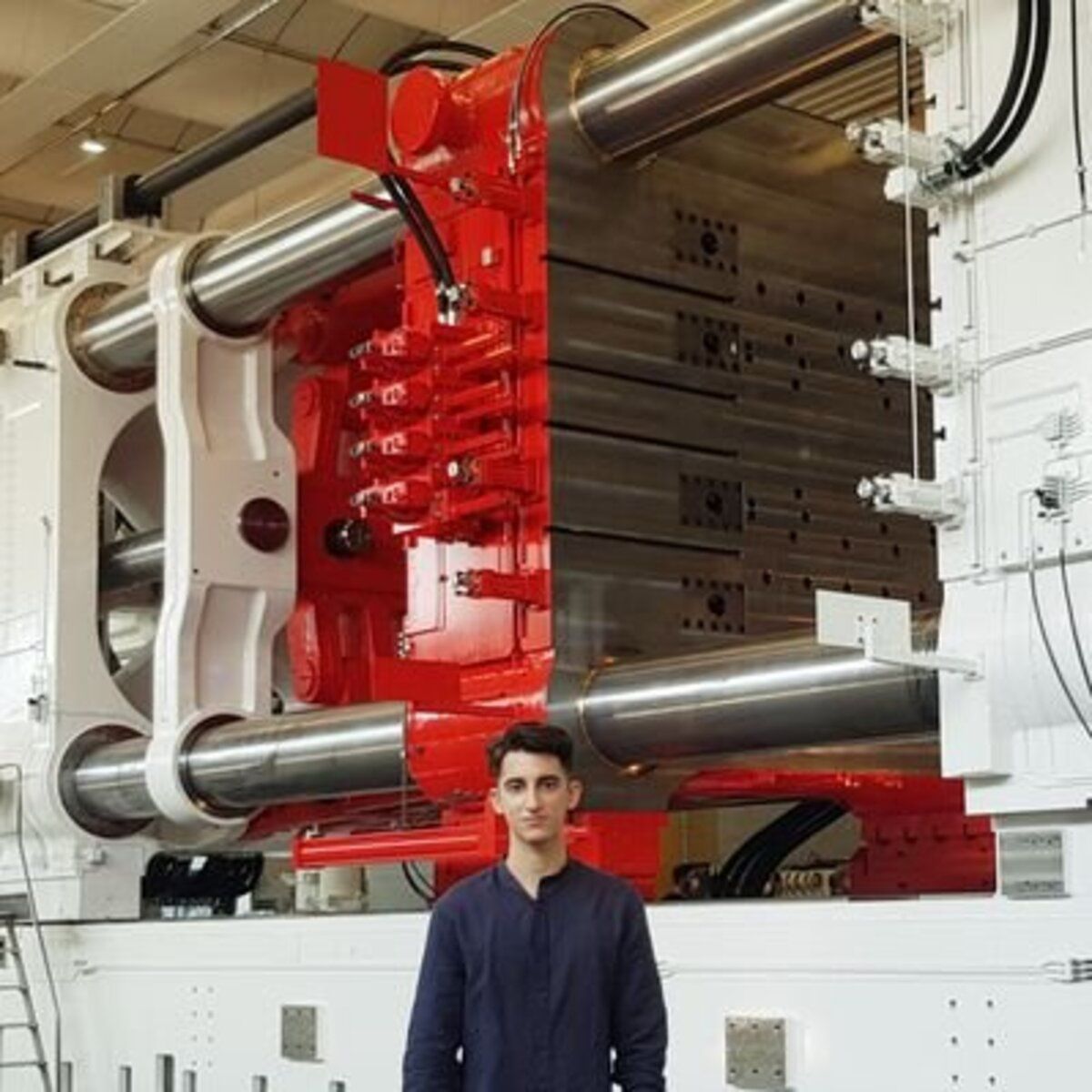

Bole Machinery Delivers Thixomolding Machine In Europe

Bole Machinery delivered a 300 ton magnesium Thixomolding machine to the Neue Materialien Fürth (NMF) in Germany.

With this installation Bole intends to demonstrate its technology to European manufacturers who want to satisfy the hunger of automotive companies for magnesium parts. As OEMs aim to differentiate their supply chain of magnesium products from China to the West, we need more investments in the Western magnesium supply chain.

I am confident that together we will make a dent in the world of metal processing and show our customers new economic ways of manufacturing metal parts.

Save the date: 14th of January 2026, in the afternoon at NMF in Fürth, Germany, where we will show you the possibilities that already exist for reducing your costs and the developments we will be driving forward in the future.

We look forward to hearing about your tasks and problems starting today.

Example of components made with a Bole MTX 300. Images kindly provided by Timo Günzel.

About NMF

Neue Materialien Fürth GmbH is an application-oriented state research institution of the Free State of Bavaria. Its goal is to translate new materials and manufacturing processes into industry-relevant solutions in close cooperation with research institutes and industry partners.

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

GF Casting Solutions First Shot Of 6100 ton Gigacasting Machine

On November 11 2025, GF Casting Solutions ran the first shot of their Gigacasting machine with a clamping force of up to 6,100 tons in Augusta, Georgia.

GF Casting Solutions, recently acquired by Nemak, is set to become the first Gigacasting capable supplier in the United States of America. The factory will be supporting the North American automotive industry starting from 2026.

This project is part of a major investment by GF Casting Solutions to become a global supplier of large structural castings for the automotive industry. All the machines for this project were and will be provided by Bühler.

In November 2024, GF’s Shenyang facility, in China, completed testing on a 6,100 ton die casting machine as part of a 7,300 square meter factory expansion. The aim is to meet the escalating demand for larger structural components at the forefront of modern "body in white" innovations. Shenyang has already been a supplier to major OEMs including BMW, Audi, Volvo, and FAW.

In Europe GF Installed another 6,100 ton machine and in the U.S. they invested $184 million at the new plant in Augusta, which will house two 6,100 ton die casting machines and employ 350 people.

GF Casting Solutions is the first Gigacasting capable supplier in the US, but before them, other OEMs and suppliers installed large die casting machine in the USA and North America, including Tesla, Honda, Ford and more.

Consider checking out The Gigacasting Database where you can find all the data you need about the Gigacasting industry: www.industryarsenal.com/upgrade

IDRA Group SWD

Idra delivered a NEO 5,000 and 10,000 to SWD in China and ran the first shot on the 5,000 ton die casting machine.

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: