Welcome to The Gigacasting Newsletter

New here? Subscribe for weekly updates

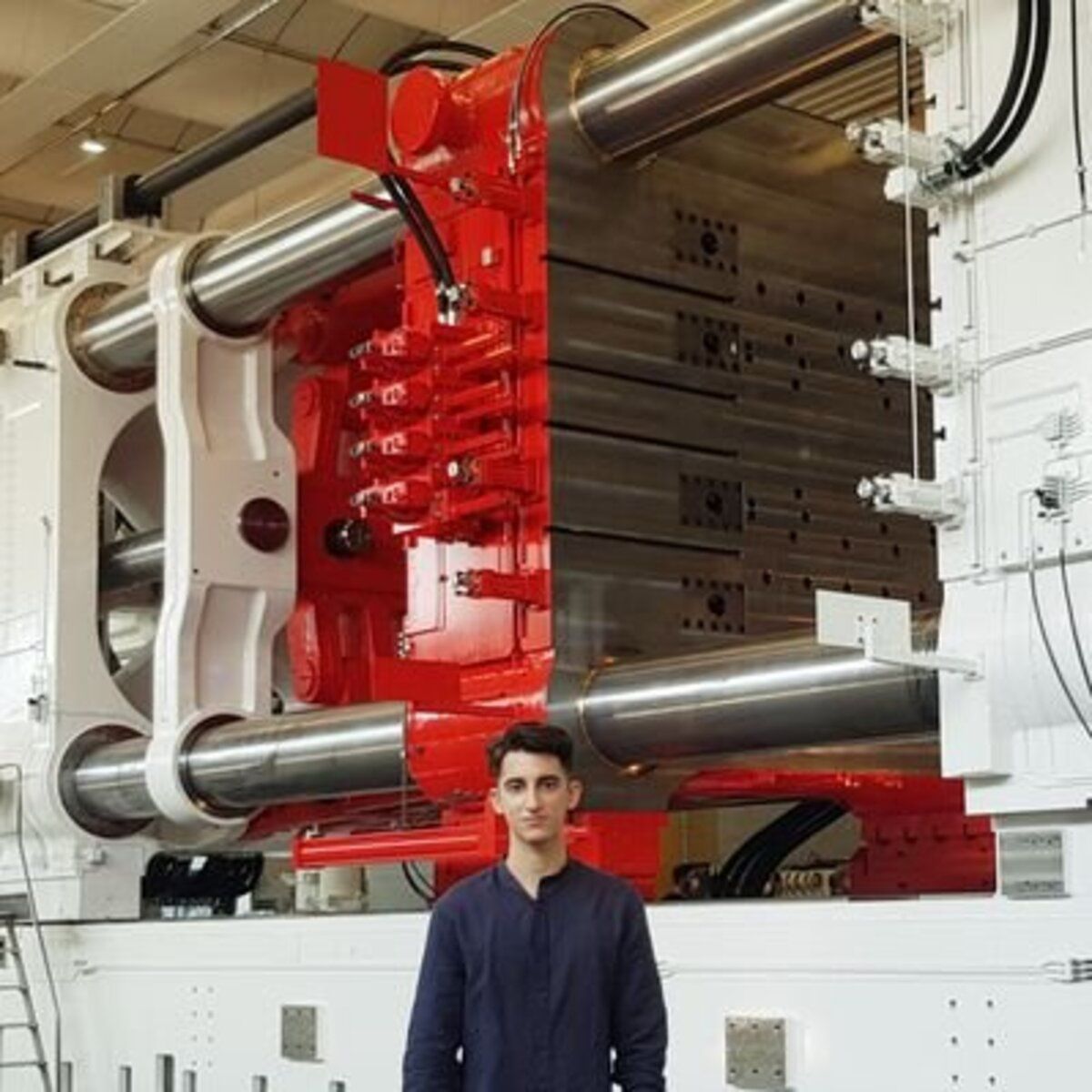

Volvo’s 8,400 ton Die Casting machine, by Bühler, is producing the rear underbody Megacastings of the new Volvo EX60.

Timo Gilgen, from automobil-produktion.de had the opportunity to visit Volvo’s Torslanda factory in Sweden and reported that production of the rear underbody Megacastings for Volvo’s new EX60, the BEV equivalent of Volvo’s best selling XC60, is in full swing.

Phil Drew, a seasoned foundry expert with decades of experience, explains what makes this technology so special: “We’ve gone from countless individual parts to a single component, a huge cast base structure.” Previously, this assembly required multiple pressing operations and tooling; now, it all happens in one step with a cycle time of just 120 seconds. “We produce a part in two minutes. Very, very fast,”

The process begins with aluminum ingots, which are melted in a gas furnace … the metal is precisely measured in a metering furnace and then injected into the mold. This mold itself weighs around 130 tons and has a modular design. "A major advantage is that the mold consists of inserts, like a puzzle," explains Peter Schüler, who is responsible for the production of the new plant. "This allows us to implement design changes much more quickly."

After casting, the part cools in a water bath, and then sprues and overflow areas are removed in a trimming press. The aluminum remnants flow directly back into the cycle. Precision is paramount. Every step is standardized to ensure the safe and predictable operation of the system. "The goal is to achieve planned and predictable production," says Schüler. "Standardization is just as important as the machine itself."

Bühler Carat 840 assembled in Torslanda, October 2023

The facility is the first of its kind in Volvo's global production network and is considered preparation for the next generation of vehicles. For the complete picture, every vehicle that uses Gigacasting and every Gigacasting machine installed worldwide, and other detailed specifications, visit The Gigacasting Database (monthly & quarterly plan now available).

Currently, the team is focusing on the EX60, but the modular design allows for the future production of other structural components such as battery housings or cross members. But even with all the technology, the process remains demanding.

Drew sums it up succinctly: "If it were easy, everyone would be doing it." The 8,400 ton machine is currently being prepared for the introduction of the new EX60. Larger components are possible, but every additional percentage point of precision means weeks of coordination between the foundry, toolmaking, and production.

Megacasting is not just a technology project, but an organizational one as well. Torslanda is systematically building up the necessary expertise. Employees were sent to Italy for tool assembly, and teams trained with a local partner in handling molten aluminum. In mold maintenance, crane and turning processes standardize the safe handling of the multi-ton tools. Each machine has three molds in circulation, one in production, one as a spare, and one undergoing maintenance.

The new EX60 will celebrate its world premiere on January 21st. It is the first vehicle whose load-bearing structure is partly manufactured using the new Megacasting plant. Peter Schüler is well aware of the significant responsibility involved: "Of course, there's pressure on the shop floor; we're directly connected to the company's cash flow." But his confidence is palpable: "We'll manage it. We have the right strategy and a strong team."

Looking further ahead, the industry is focusing on the long term. Drew points to the vision driving megacasting worldwide: "The ultimate goal is to produce an entire car in a single casting." That's still a long way off, but the direction is clear.

For Volvo, Torslanda is therefore more than just a site steeped in tradition. It's a learning environment where technology, organization, and culture mutually shape one another. The path to this requires discipline, patience, and a willingness to embrace new ideas. Phil Drew sums it up perfectly at the end of his tour through the megacasting hall: "This isn't just a machine. It's the beginning of a new way of building cars."

About Torslanda

Torslanda is the heart of Swedish production, both a symbol and its backbone. Since 1964, more than 9.5 million vehicles have been manufactured here. In 2024, the plant celebrated its 60th anniversary and is simultaneously in the process of reinventing itself. With an annual output of around 280,000 units, Torslanda contributes approximately 40 percent to total production. 6,000 production workers and 340 office staff keep the plant running around the clock.

Traditionally, the larger models roll off the assembly line here: the XC90, the best-selling XC60, the V60, and until recently, the station wagon versions V90 and V90 Cross Country. But their place is now being made available for the EX60.

Source: automobil-produktion.de