Welcome to The Gigacasting Newsletter

New here? Subscribe

Volkswagen Embraces Gigacasting

At the IAA Mobility 2025 event in Munich, held September 9-14, 2025, Volkswagen held a Technology Day presentation where they announced the adoption of Gigacasting for several upcoming entry-level EVs.

The initial strategy includes integrating a large aluminum casted battery tray, or better, the frame of the tray. This technology will first be adopted by the brand new VW ID. Polo, Cupra Raval, and Škoda Epiq, as well as the VW ID. Cross (production version not unveiled yet).

Dr. Marc Adam, during the session, discussed the future of large castings, emphasizing benefits like reduced production time, lower complexity, and cost savings, while noting possible plans for new facilities equipped with 8,400 ton die casting machines focused on integration, productivity, and efficiency.

The presentation also provided an outlook on expanding VW's casting strategy, positioning it as a milestone for high-volume EV platforms.

Volkswagen has not taken a final decision on integrating front and rear underbody Gigacastings, but it was made clear that should they decide to follow the “Tesla route” in the future, then they will require larger machines, such as 8,400 tons which were mentioned during the presentation.

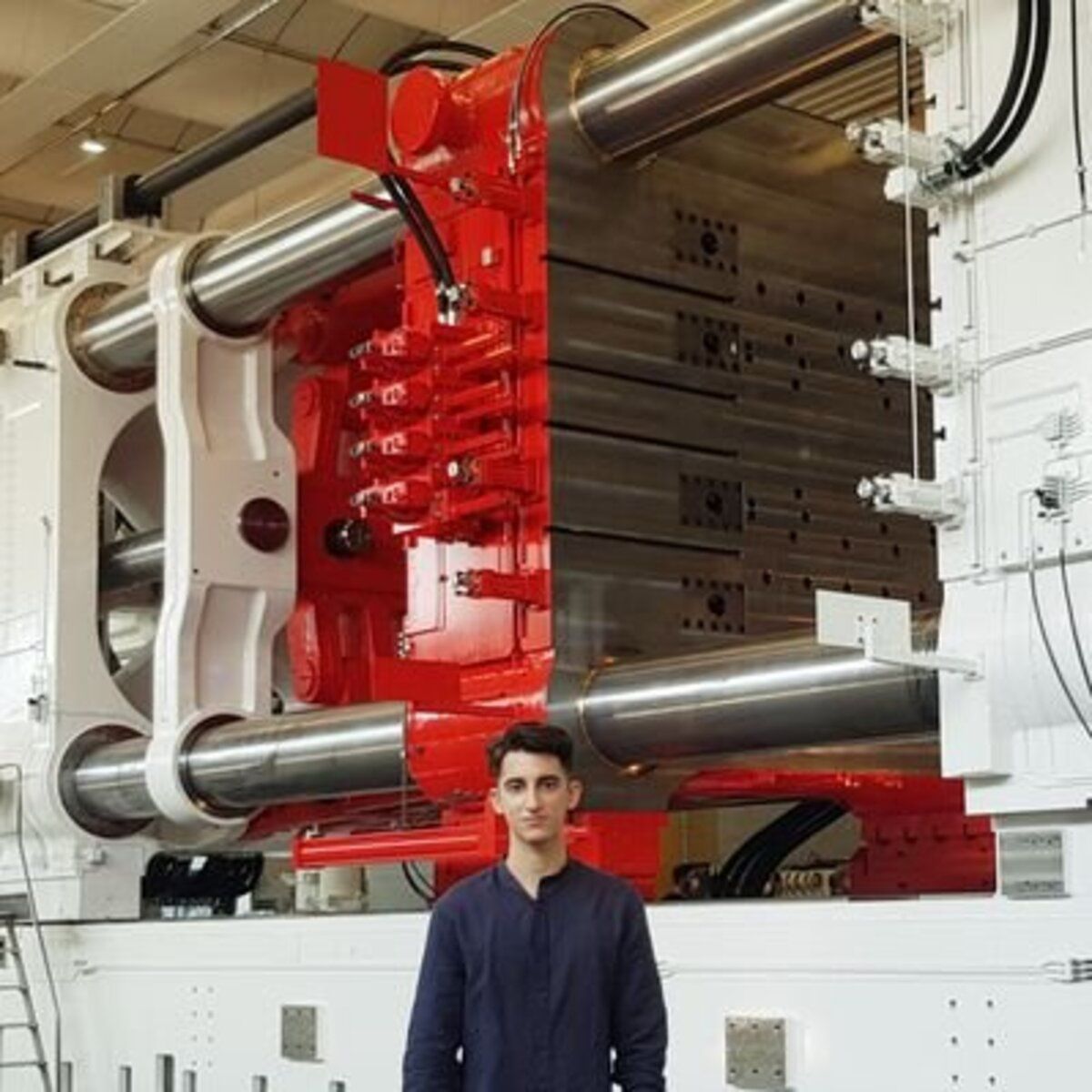

Credit: Martin Lagler

Smaller front and rear Gigacastings made with 4,400 ton machines in Kassel, Germany were showed at the event (see them below) but these serve as pathfinders, key for R&D efforts and will not be present in VW future models.

Credit: Martin Lagler

The Battery Frame

The battery frame presented will be Volkswagen’s first Gigacasting application in its vehicles. These include The Electric Urban Car Family lineup, ID. Polo, ID. Cross Concept, Cupra Raval and Skoda Epiq.

It is the German Group’s most complex casting yet, 1.7 m long, 1.15 m wide, which replaces 123 individual parts and helps reduce weight by 10%.

Further details describe a 120 seconds cycle time and the use of 3 plate die technology. The cost reduction is 15%.

This battery frame is a very interesting solution and it differentiate itself from other Gigacast battery trays which we have seen in the past.

Credit: Volkswagen

Honda is also adopting a die casted battery tray, but it includes the entire floor which is a very large surface that increases the clamping force needed to lock the die in place during the die casting process.

This translated to the need for larger machines, as we have seen, Honda uses 6,100 ton machines in Ohio to produce just half of the battery tray, while in China, they make the entire tray in one shot utilizing a 12,000 ton die casting machine.

Instead Volkswagen focuses on the frame of the battery tray, avoiding the larger flat surfaces but still integrates a lot of components. It appears that a lot of connection points for internal components, such as battery cells/modules, management and cooling system should be present in the frame.

Another key aspect of this design choice is weight. Volkswagen will likely fill the voids in the floor with other components that will likely be much lighter and thinner than what you can achieve with die casting.

Credit: Volkswagen

This is beneficial because the battery frame is produced using only a 4,400 ton die casting machine, as we have seen in Kassel, earlier this year.

While official VW press releases from IAA focused more on AI, batteries, bidirectional charging, and design, the Gigacasting details emerged through attendee reports and social media, with no public video or full transcript readily available from VW.

Tesla High Volume Panel Assembly Patent

Tesla was granted a patent related to their unboxed manufacturing process, where several sub-sections of the car get assembled on parallel production lines and then put together in the final assembly.

The patent describes an automated system for assembling exterior vehicle parts onto the main body in white.

It uses an assembly cell with fixtures tailored to each part, aligned to a global datum for precision.

Parts are secured to fixtures via vacuum clamps or other means, and a structural adhesive is applied to the part or its designated location on the vehicle structure.

A robotic positioner moves the parts into their nominal positions, compressing the adhesive to complete installation.

An engineered adhesive gap compensates for substructure irregularities to ensure consistent alignment.

Tacking operations, using self-piercing datums or hot melt adhesives, allow continued assembly while the primary adhesive cures.

This method reduces manual labor, minimizes errors, and improves production rates by automating precise part placement.

The system includes:

"An automated assembly cell with a respective fixture for each exterior vehicle part.

A global datum for aligning the exterior vehicle parts within the automated assembly cell.

A securing mechanism for holding an exterior vehicle part to a respective fixture using a vacuum clamp or other clamping means.

A robotic adhesive arm for applying a structural adhesive to a clamped exterior vehicle part or to a part-receiving location on the vehicle assembly structure.

A robotic part positioner for moving the clamped exterior vehicle part into a nominal position relative to the global datum to compress the structural adhesive and complete installation of the clamped exterior vehicle part to the vehicle assembly structure, wherein the system is configured to provide an adhesive a to compensate for irregularities in an exterior vehicle part a fixture, or a substructure of the vehicle assembly structure."

According to Tesla’s CEO Elon Musk, the most important aspect about this patent and the unboxed manufacturing process is to get the cycle time to 10 seconds, ideally to just 5.

FAW Magnesium Thixomolding production base

FAW has made significant strides in establishing its magnesium alloy production base. The facility has successfully installed and commissioned the 850 ton magnesium alloy thixomolding machine along with CNC machines, and deburring systems.

Following the successful trial of the automated production process on August 6th, the plant has now achieved full-scale production for instrument brackets. Steering wheel frames are next.

A 3,600 ton magnesium thixomolding machine is being installed and will produce door inner panels, full cross car beams (CCB) and other structural components for vehicles.

FAW’s 850 ton thixomolding machine from Haitian

More Magnesium Thixomolding Capacity Built in China

On September 16, Qingyang County Industrial Park Management announced the winning bids for the “demonstration production line project” for an annual production of 1.5 Million magnesium thixomolded products. Yizumi and Haitian secured the contracts for the first and second packages for the procurement of thixomolding equipment.

The project involves constructing four 700-850 ton thixomolding islands, complemented by advanced automation systems, including robots, high-precision CNC machining lines, and testing equipment.

Yizumi won package 1, which includes two 700 ton thixomolding units. Meanwhile, Haitian secured package 2, comprising two 850 ton thixomolding machines.

Quick News

Tesla Aluminum Recycling

The recycling operations at Tesla’s GigaFoundry in Austin, Texas are picking up. A lot of new scrap material from non-Tesla sources is brought in every week and quickly melted. Additionally, a new giant furnace loading mechanism is being assembled.

This is the world’s largest Gigacasting shop and produces parts for three different Tesla models.

Keep track of Tesla’s Gigacasting operations around the world along with every other OEM and supplier investing in this technology at industryarsenal.com

Li Auto i6

The newly presented i6 is Li Auto’s third fully electric model and just as their first two BEVs, it features a rear underbody Gigacasting.

Although similar in look, it’s not the same as the Li Auto i8. The i6 is shorter than the i8 and has a 5 seats configuration vs 6 seats for the i8.

Last Article: