Welcome to The Gigacasting Newsletter

New here? Subscribe

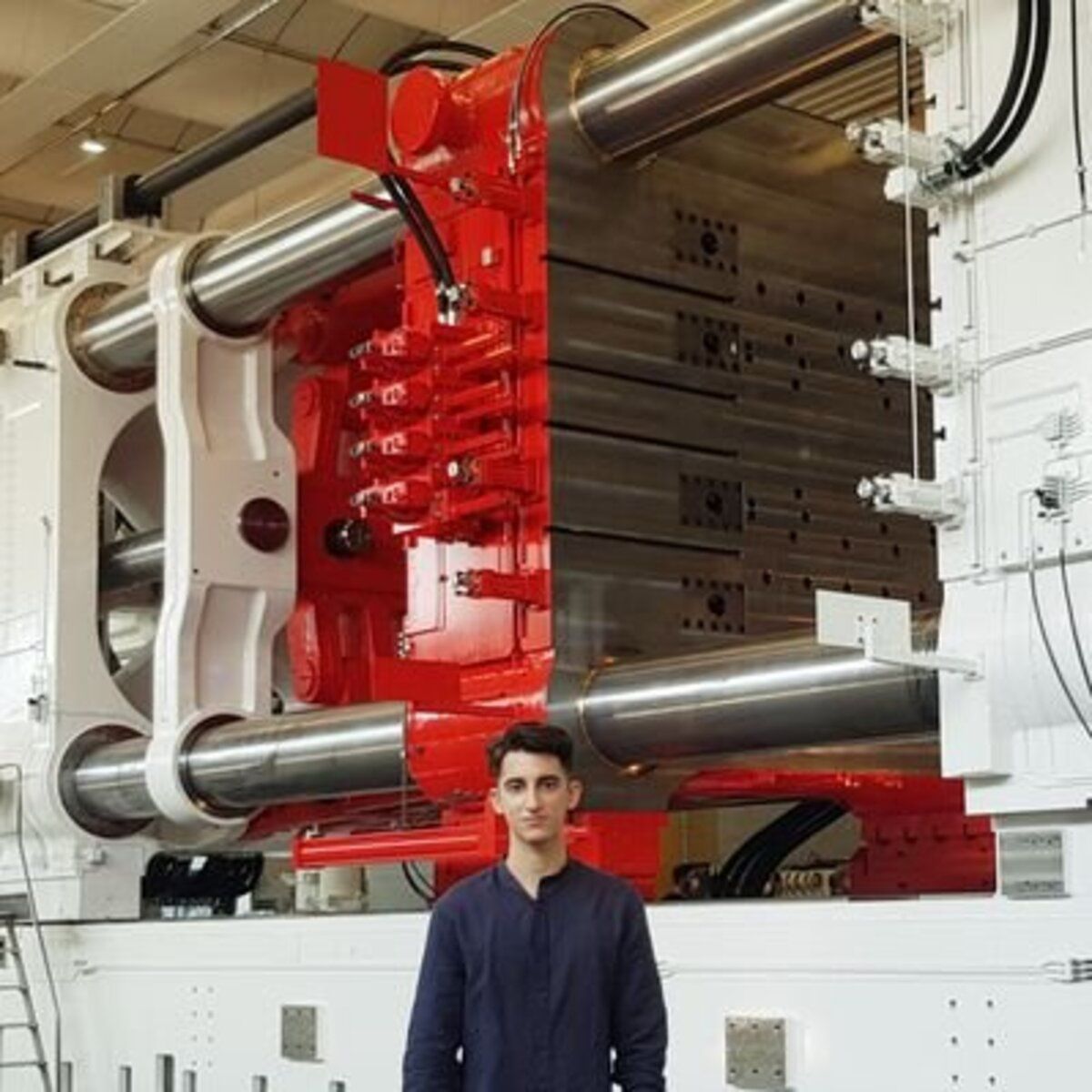

First Look At BYD's 9000T Gigacasting Process

A BYD executive, He Zhiqi, shared information on his Weibo account regarding BYD's 9,000 ton die casting production line;

In the afternoon, I went to the factory to see the new car trial production and took the opportunity to visit our 9,000 ton large die casting production line.

The front and rear cabin floors were previously welded from 74 stamping parts to a single large die cast aluminum part, which greatly improved efficiency and reduced weight.

The equipment is domestically produced, and the molds are made by BYD.

From aluminum ingot to finished product, it is fully automated, which was unimaginable before.

I like the great progress of Made in China 👍

Previously, it was reported that BYD had invested in the construction of an "integrated body" die casting project, aka Gigacasting, for the future platform of its vehicles.

The initial investment consisted in 390.5 million Yuan ($54 million at the time) for the construction of a Gigacasting shop and the purchase of one 9,000 t die casting machine and its related supporting equipment.

Additional info revealed the plan is to adopt heat treatment free Al alloys and utilize both Front and Rear Underbody Gigacastings.

Later, general manager of the sales division of Denza (a BYD brand), reposted and shared optimism for the future of Gigacasting and die casting for body in white applications.

Large-scale die-casting is poised for significant growth in the automotive industry this year...

Using ultra-large die-casting machines, allows dozens or even hundreds of parts, previously requiring stamping and welding, to be die-cast in a single operation.

Applications are also expanding: from the current rear underbody, front engine compartment, and battery tray applications, they are gradually expanding to include mid-sections, seat frames, door frames, and even the integration of the entire vehicle body-in-white.

Integrated die-casting … can significantly improve efficiency, reduce costs, and enhance vehicle performance. As the technology matures and the industry continues to collaborate and innovate, it will expand even faster and encompass more diverse areas.

Share this article individually from here

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

🔎 Search companies installing Gigacasting machines, vehicles adopting this technology, as well as future vehicles and platforms and much more!

Gigacastings Save on Vehicle Repairs

Gigacasting technology reduces vehicle production costs for automakers while also lowering repair expenses for consumers and insurers, according to a two-year study on crash testing and damage assessment by U.K. based automotive technology specialist Thatcham Research, reported in an interview by Wardsauto.

The study found that Gigacasting, currently used by Tesla and a dozen OEMs in China, while still in development by all Western, Japanese and Korean OEMs, can significantly decrease repair costs and potentially reduce vehicle write-offs for insurers.

A key advantage of Gigacasting lies in designing components with repairability in mind from the outset, says Richard Billyeald, Thatcham’s chief research and operations officer.

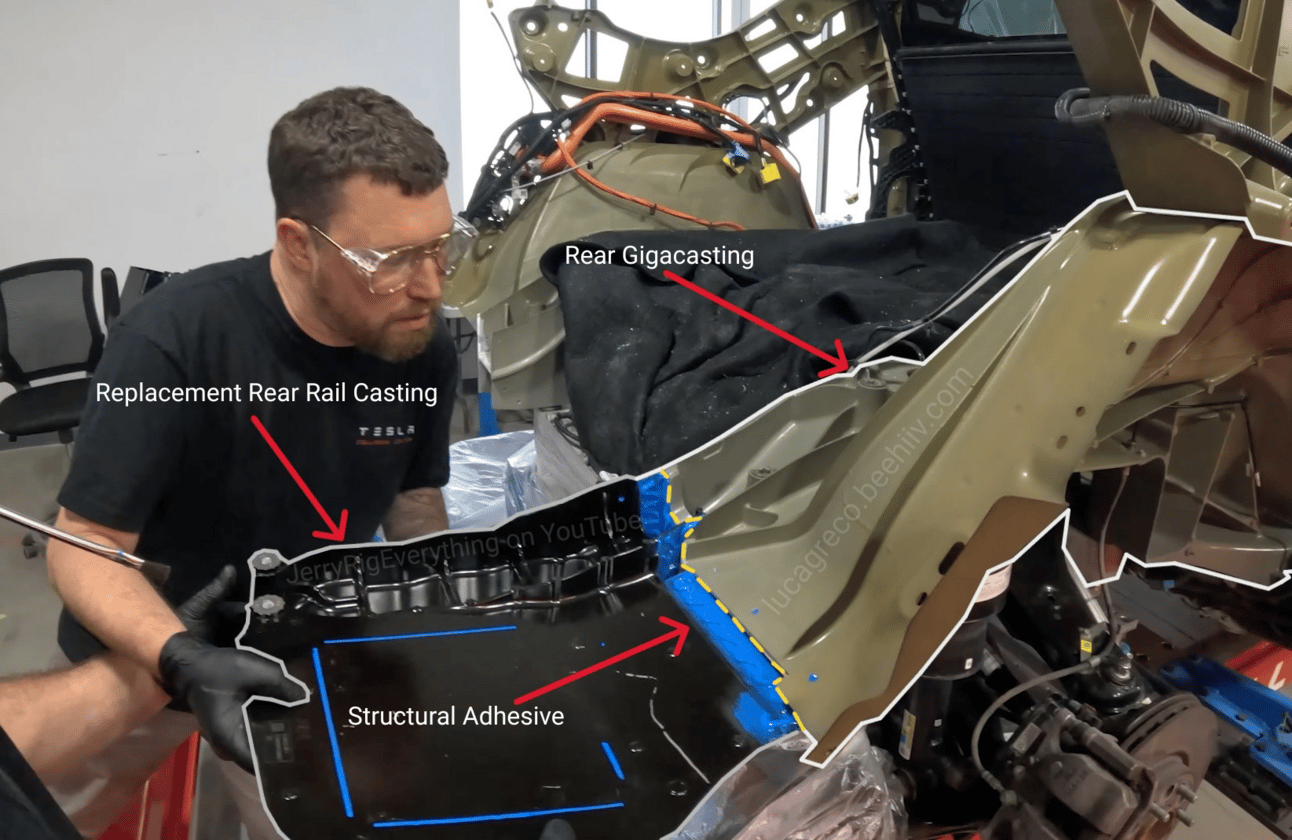

The fact that you can section the vulnerable bits of the casting - and Tesla has a specific repair item that wedges in and bolts through, to address the issue of one large unit - that’s the sort of stuff that really makes a difference

Check out my article about a documented repair case of the rear Gigacasting of a Tesla Cybertruck.

Tesla collision center repairing a damaged Tesla Cybertruck

The research addressed insurer concerns about the cost of repairing large, single-piece aluminum castings, particularly after rear-end collisions, one of the most common no-fault accidents.

Thatcham’s study utilized real-world claims data from U.K. insurers and Germany’s Allianz Centre for Technology (AZT). Extensive crash testing was conducted at Thatcham’s Berkshire, England, headquarters, focusing on Tesla Model Y vehicles featuring a single-piece aluminum rear floor section.

The analysis revealed that Gigacasting lowers repair costs in both partial and full replacement scenarios compared to traditional multi-piece steel structures.

For instance, partial repairs on the Tesla Model Y yielded a £2,167 ($2,932) savings over similar repairs on a Tesla Model 3 with a conventional multi-part steel rear sub-assembly, while full replacements saved £519 ($702).

Comparable savings were observed when benchmarking against other vehicles, including the Mercedes EQE, Hyundai Ioniq 5, and several internal-combustion-engine models.

Low-severity crash tests at 15 km/h (9.3 mph) showed the gigacast sustaining no structural damage, enabling full vehicle repairs without replacing the gigacast component. In medium-severity tests at 25 km/h (15.5 mph), crack propagation and structural misalignment necessitated full gigacast replacement.

However, at £716 ($969) for the component, repair costs remained competitive or lower than traditional methods for equivalent damage.

Tesla Model Y rear casting

These results counter initial industry concerns about the fragility of large single-piece castings in minor impacts, says Billyeald.

What Tesla has come up with is to section these areas and then the repair parts can be bolted and glued so you are not having to work the aluminum sections and the repair process becomes all mechanical, making it much more manageable

However, the study highlighted challenges. Repairs requiring welding of aluminum gigacast structures must occur at Tesla-approved facilities, raising concerns about repair network capacity as the technology spreads. This could lead to vehicle transfers between repair centers, increasing time and costs.

Thatcham’s principal engineer for automotive repair, Darren Bright, emphasized that Gigacasting simplifies repairs compared to traditional methods.

I think the layering of the panels are key. If you imagine 90 separate panels made of aluminum held together with rivets and adhesive, the amount of trial fitments, dry-run fitments that you have to do to fit these panels together, lining everything up, press the holes for the rivets.

Then you multiply that by how many separate joints you have, (and) there are a lot of potential points of failure in repair, such as putting a hole in the incorrect place – the worst thing you can do!

Bright noted that Tesla’s replaceable cast rear rail assemblies, costing just £31 ($42) each, address most minor impacts. Unlike most aluminum-bodied vehicles that rely on riveting, Tesla’s gigacast unit uses two long welded joints.

“So, on the Tesla, you can drill the welds out with a couple of additional bolted fixings… and then you are just putting rivets back. Really, quite a simple process” he explains.

Billyeald emphasized that while automakers adopt Gigacasting to cut production costs, poor design could compromise performance in collisions compared to traditional multi-piece components.

Tesla Model Y rear cast rail

The real lesson here for carmakers and insurers is when the repairability has been considered at the design stage and methods and strategies for repair are implemented as part of that, you get a good result.

It’s the thing that Tesla has done well.

Interview conducted by Paul Myles. Source: Wardsauto

Share this article individually from here

The Sub-Assemblies For Tesla’ Unboxed Process Were Spotted At The Fremont Factory

In Weekly Gigacasting News issue 39, I reported about unidentified vehicle components which were observed at Tesla’s Fremont factory in California.

I speculated that they could be a body in white section of the Tesla Cybercab, specifically, the rear sub assembly built on top of the rear underbody (RUB) Gigacasting.

Left: Items spotted at Fremont. Right: Cybercab RUB Gigacasting

Tesla's "Unboxed" process is a manufacturing technique for electric vehicles that replaces the traditional linear assembly line, where vehicles move sequentially through stations for part additions, with a modular approach.

Instead, key sections of the car (such as the front, rear, battery pack, and side panels) are assembled in parallel sub-lines as independent modules, then integrated in a final assembly stage.

This method aims to reduce production costs, shrink factory footprints by 40%, and accelerate output.

Note the sub assemblies are examples from the Model Y and Cybertruck

A friend of Tesla, Joe Tegtmeyer who visited the Fremont factory, was able to confirm my speculation, furthermore he took a closer look the video and spotted more sub-assembly sections, including the front underbody Gigacasting of the Tesla Cybercab.

Additional information from Joe Tegtmeyer

The Cybercab Front and Rear Gigacastings which are solely produced at Tesla’s factory in Texas are shipped to Fremont, California for the testing and development of the Cybercab and the unboxed manufacturing process.

Check out Joe’s YouTube channel.

Wencan General Updates

Wencan Group will open a new Gigacasting factory in China, with production slated to begin in November 2025, serving automotive customers in Guangdong province.

The facility will be equipped with 19 die casting machines ranging from 2,200 to 12,000 tons, with the potential to install 16,000 ton machines as needed.

It was reported that a 9,000 ton die casting machine has already been installed.

Designed to produce 40,000 tons of aluminum components annually for the electric vehicle industry, the plant will manufacture electric motor housings, battery trays, body castings, and underbody Gigacastings.

At the same time, local media from Chongqing reported that the installation of two 12,000 ton die casting machines is underway at Wencan’s local facility.

image from one of the Wencan Group factories

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: