Welcome to The Gigacasting Newsletter

New here? Subscribe for weekly updates

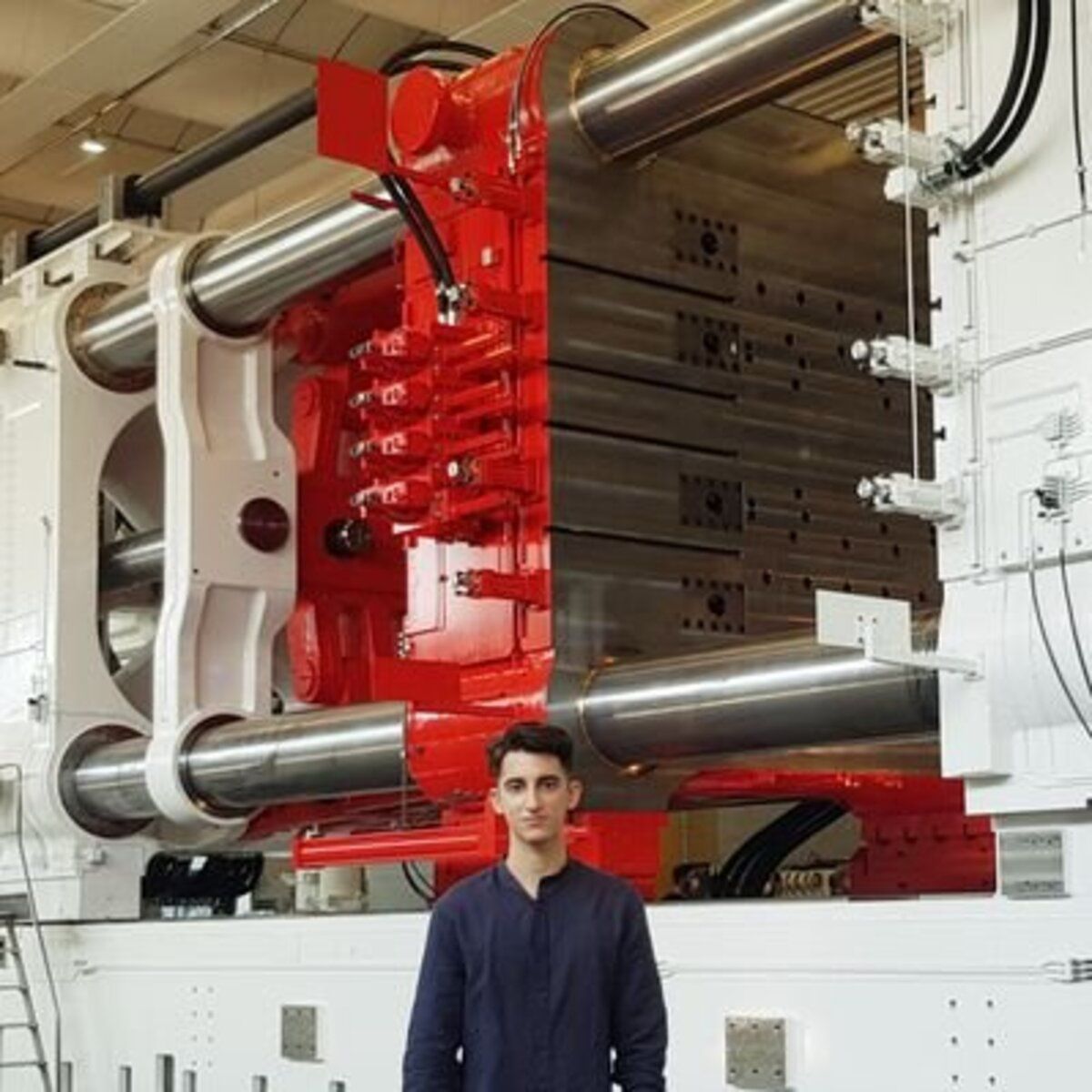

A BYD executive, He Zhiqi, shared information on his Weibo account regarding BYD's 9,000 ton die casting production line;

In the afternoon, I went to the factory to see the new car trial production and took the opportunity to visit our 9,000 ton large die casting production line.

The front and rear cabin floors were previously welded from 74 stamping parts to a single large die cast aluminum part, which greatly improved efficiency and reduced weight.

The equipment is domestically produced, and the molds are made by BYD.

From aluminum ingot to finished product, it is fully automated, which was unimaginable before.

I like the great progress of Made in China 👍

Previously, it was reported that BYD had invested in the construction of an "integrated body" die casting project, aka Gigacasting, for the future platform of its vehicles.

The initial investment consisted in 390.5 million Yuan ($54 million at the time) for the construction of a Gigacasting shop and the purchase of one 9,000 t die casting machine and its related supporting equipment.

Additional info revealed the plan is to adopt heat treatment free Al alloys and utilize both Front and Rear Underbody Gigacastings.

Later, general manager of the sales division of Denza (a BYD brand), reposted and shared optimism for the future of Gigacasting and die casting for body in white applications.

Large-scale die-casting is poised for significant growth in the automotive industry this year...

Using ultra-large die-casting machines, allows dozens or even hundreds of parts, previously requiring stamping and welding, to be die-cast in a single operation.

Applications are also expanding: from the current rear underbody, front engine compartment, and battery tray applications, they are gradually expanding to include mid-sections, seat frames, door frames, and even the integration of the entire vehicle body-in-white.

Integrated die-casting … can significantly improve efficiency, reduce costs, and enhance vehicle performance. As the technology matures and the industry continues to collaborate and innovate, it will expand even faster and encompass more diverse areas.

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!