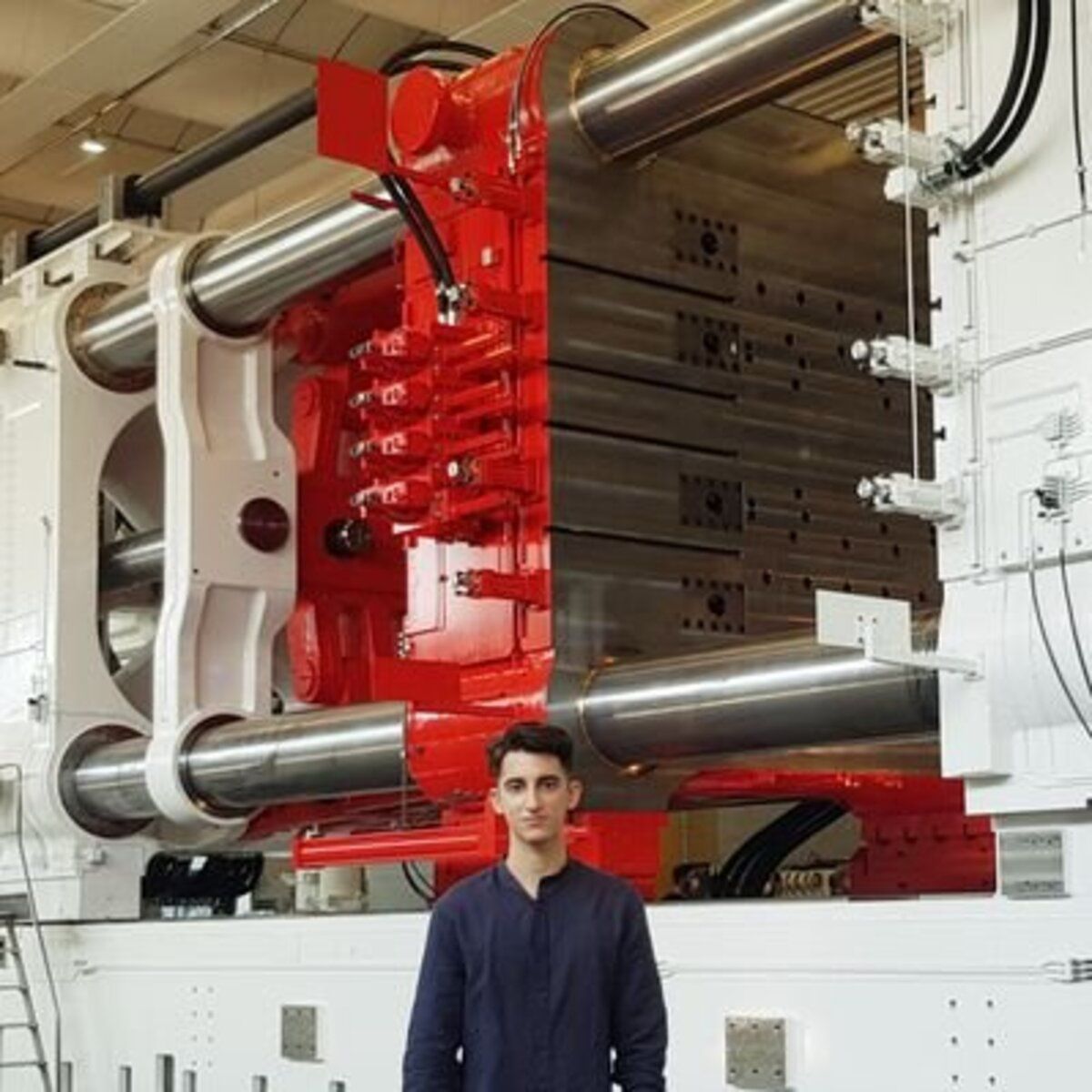

Welcome to The Gigacasting Newsletter

New here? Subscribe for weekly updates

Gigacasting technology reduces vehicle production costs for automakers while also lowering repair expenses for consumers and insurers, according to a two-year study on crash testing and damage assessment by U.K. based automotive technology specialist Thatcham Research, reported in an interview by Wardsauto.

The study found that Gigacasting, currently used by Tesla and a dozen OEMs in China, while still in development by all Western, Japanese and Korean OEMs, can significantly decrease repair costs and potentially reduce vehicle write-offs for insurers.

A key advantage of Gigacasting lies in designing components with repairability in mind from the outset, says Richard Billyeald, Thatcham’s chief research and operations officer.

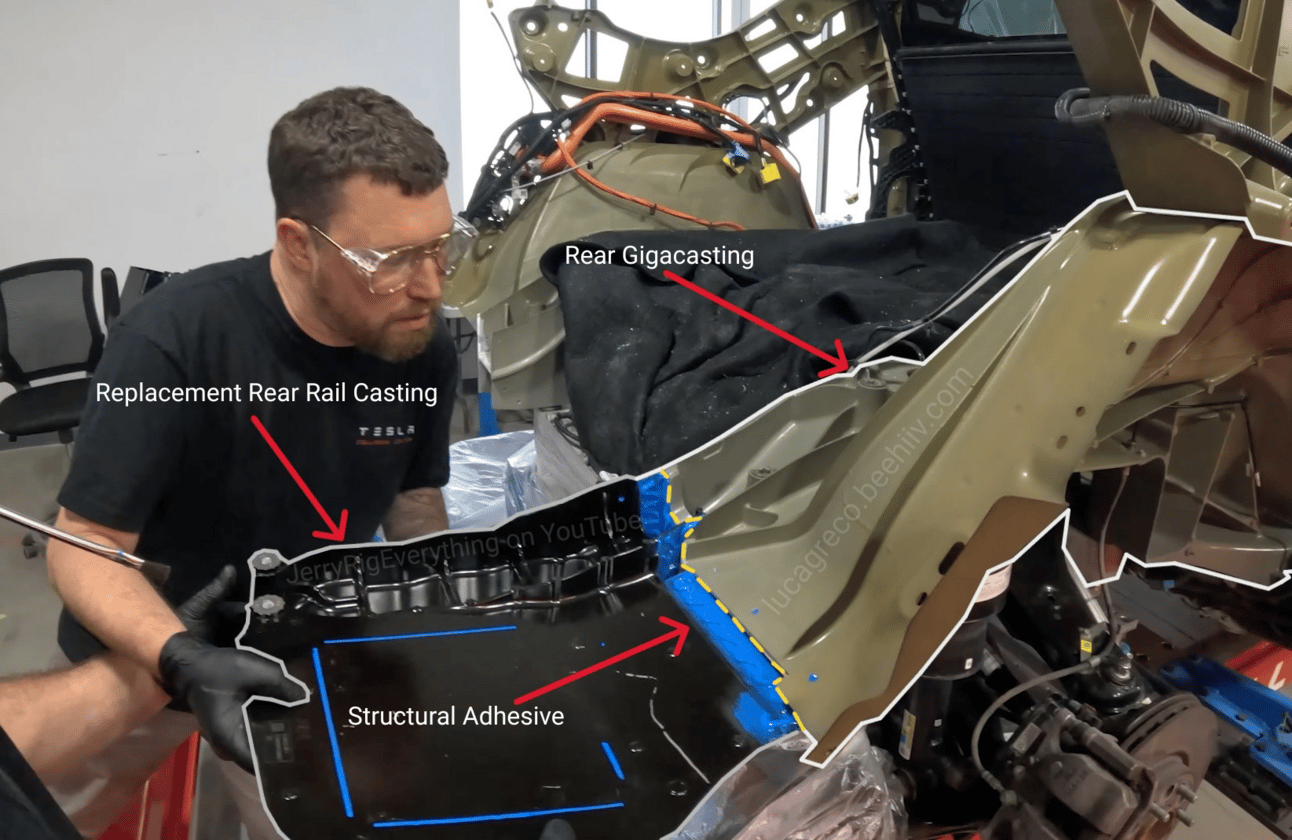

The fact that you can section the vulnerable bits of the casting - and Tesla has a specific repair item that wedges in and bolts through, to address the issue of one large unit - that’s the sort of stuff that really makes a difference

Check out my article about a documented repair case of the rear Gigacasting of a Tesla Cybertruck.

Tesla collision center repairing a damaged Tesla Cybertruck

The research addressed insurer concerns about the cost of repairing large, single-piece aluminum castings, particularly after rear-end collisions, one of the most common no-fault accidents.

Thatcham’s study utilized real-world claims data from U.K. insurers and Germany’s Allianz Centre for Technology (AZT). Extensive crash testing was conducted at Thatcham’s Berkshire, England, headquarters, focusing on Tesla Model Y vehicles featuring a single-piece aluminum rear floor section.

The analysis revealed that Gigacasting lowers repair costs in both partial and full replacement scenarios compared to traditional multi-piece steel structures.

For instance, partial repairs on the Tesla Model Y yielded a £2,167 ($2,932) savings over similar repairs on a Tesla Model 3 with a conventional multi-part steel rear sub-assembly, while full replacements saved £519 ($702).

Comparable savings were observed when benchmarking against other vehicles, including the Mercedes EQE, Hyundai Ioniq 5, and several internal-combustion-engine models.

Low-severity crash tests at 15 km/h (9.3 mph) showed the gigacast sustaining no structural damage, enabling full vehicle repairs without replacing the gigacast component. In medium-severity tests at 25 km/h (15.5 mph), crack propagation and structural misalignment necessitated full gigacast replacement.

However, at £716 ($969) for the component, repair costs remained competitive or lower than traditional methods for equivalent damage.

Tesla Model Y rear casting

These results counter initial industry concerns about the fragility of large single-piece castings in minor impacts, says Billyeald.

What Tesla has come up with is to section these areas and then the repair parts can be bolted and glued so you are not having to work the aluminum sections and the repair process becomes all mechanical, making it much more manageable

However, the study highlighted challenges. Repairs requiring welding of aluminum gigacast structures must occur at Tesla-approved facilities, raising concerns about repair network capacity as the technology spreads. This could lead to vehicle transfers between repair centers, increasing time and costs.

Thatcham’s principal engineer for automotive repair, Darren Bright, emphasized that Gigacasting simplifies repairs compared to traditional methods.

I think the layering of the panels are key. If you imagine 90 separate panels made of aluminum held together with rivets and adhesive, the amount of trial fitments, dry-run fitments that you have to do to fit these panels together, lining everything up, press the holes for the rivets.

Then you multiply that by how many separate joints you have, (and) there are a lot of potential points of failure in repair, such as putting a hole in the incorrect place – the worst thing you can do!

Bright noted that Tesla’s replaceable cast rear rail assemblies, costing just £31 ($42) each, address most minor impacts. Unlike most aluminum-bodied vehicles that rely on riveting, Tesla’s gigacast unit uses two long welded joints.

“So, on the Tesla, you can drill the welds out with a couple of additional bolted fixings… and then you are just putting rivets back. Really, quite a simple process” he explains.

Billyeald emphasized that while automakers adopt Gigacasting to cut production costs, poor design could compromise performance in collisions compared to traditional multi-piece components.

Tesla Model Y rear cast rail

The real lesson here for carmakers and insurers is when the repairability has been considered at the design stage and methods and strategies for repair are implemented as part of that, you get a good result.

It’s the thing that Tesla has done well.

Tesla Cybertruck Lead Engineer & Sr. Director Engineering, Wes Morrill commented on X

Interview conducted by Paul Myles. Source: Wardsauto

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!