Welcome to The Gigacasting Newsletter

New here? Subscribe

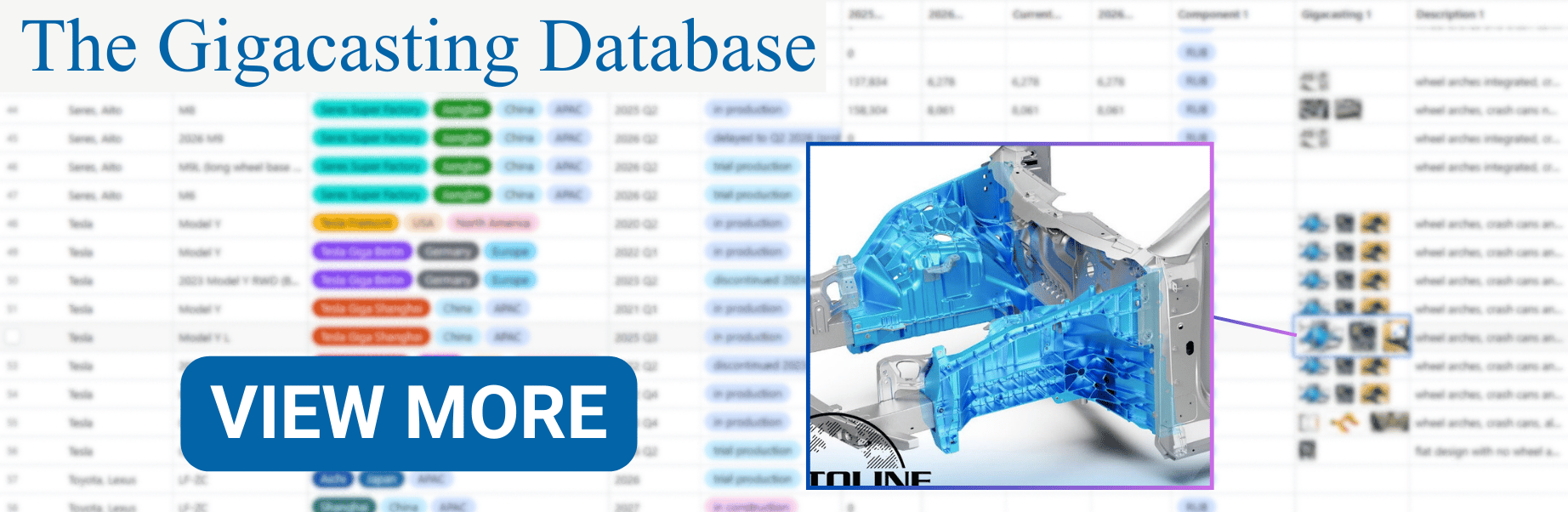

ItalPresseGauss Will Deliver A 5,200 ton Machine To BMW

Five years ago, BMW installed a TF 5700, at the time the largest die casting machine in Europe. The machine enabled the redesign of a crash-resistant battery housing, transforming a previous 16-piece assembly into a single, lightweight aluminum part.

This achievement reduced weight, simplified production, and enhanced safety, demonstrating the precision and power that ItalPresseGauss machines can provide.

On January 13th 2026, IPG announced it has been commissioned to supply a TFs 5200 to BMW, a machine engineered to deliver high efficiency and exceptional precision for large, complex structural components.

The TFs 5200 is part of the new “Toggle Free Smart Series” of machines presented by ItalPresseGauss, you can read more about it here.

The TFs 5200 is adapted to be installed on the existing foundations of a machine from another HPDC equipment supplier, which had been in operation but was recently taken out of production.

IPG engineering tailored the new machine to fit the existing infrastructure with minimized impact and simpler installation. This strategy helps reduce downtime while maximizing efficiency.

Haitian Metal Struck Another Deal For Magnesium Thixomolding Machines

Haitian Metal struck a deal for the supply of magensium Thixomolding machines to Hongchuang Light Alloys.

On December 23, The two parties officially signed a strategic cooperation agreement on magnesium Thixomolding.

According to the agreement, Hongchuang Light Alloys will purchase four models of magnesium thixomolding islands from Haitian Metal: HMG500, HMG850, HMG1650, and HMG3600.

This range of machines from 500 to 3,600 tons of clamping force covers manufacturing needs from small and medium-sized precision parts to large structural parts.

Hongchuang Light Alloys is deeply involved in the R&D and production of components made of aluminum, magnesium and titanium alloys.

This investment marks the entry of Hongchuang into the semi solid forming technology of magnesium components, aiming to place itself as a supplier for the automotive, robotics and EVTOL industries.

🤖 Magnesium Thixomolding is being considered as a "process of choice" for the production of many different components for humanoid robots as well.

After the equipment is delivered, Hongchuang Light Alloys will have multiple lightweight technologies in its arsenal, including magnesium Thixomolding, extrusion and forging.

Haitian’s proposal of an automated thixomolding production line

Magrathea and Wogen Sign Offtake Distribution Partnership

Magrathea, a technology company building the US’s only new magnesium metal smelter, has formed an offtake and distribution partnership with global metals trader Wogen who will also support capitalization of Magrathea’s commercialization with a $10 million working capital commitment.

In November 2025, Magrathea signed a term sheet with TETRA Technologies to form a joint venture called Arkansas Magnesium. The joint venture will build a magnesium smelter in Southwest Arkansas at TETRA’s Evergreen chemical campus. The partnership reduces capital and operating costs by leveraging TETRA’s energy, land, supply chain, and operational capabilities.

Magrathea has non-binding offtake agreements with customers representing nearly 200,000 tonnes per year of ex-China magnesium metal demand and has pre-sold metal to a Detroit “Big 3” automaker. Magrathea has now formed another major catalytic partnership with Wogen, who will distribute a portion of the metal from Arkansas Magnesium’s Commercial Phase 1 and Phase 2 plants.

Magrathea plans to place up to 7,000 tonnes per year of magnesium into the market by 2029, taking advantage of the trading house’s experience getting metal into the hands of customers.

As part of this partnership, Wogen will contribute $10 million in working capital for Commercial Phase 2 at competitive financing terms.

“Wogen has seen it all over the past 30 years of ex-China magnesium project development efforts and we’re honored they’re choosing us to team up,” said Alex Grant, CEO of Magrathea. “We are excited to work with their team to deliver the US’s first new magnesium metal this century into the hands of major customers from aluminum companies to magnesium die casters to aerospace and automotive giants.”

“We are excited to be working with Magrathea in bringing this important producer of a critical commodity to market,” said John Craig, CEO of Wogen. “Wogen has extensive experience in the US magnesium market and we are looking forward to working with the excellent team at Magrathea as they go about developing this highly innovative producing asset.”

About Magrathea

Magrathea is a technology company founded in California that has developed a new generation of electrolytic process for making clean, secure magnesium metal from seawater and brines.

About Wogen

Wogen is a global metals and minerals trading company headquartered in London. They specialize in sourcing, marketing, and distributing a wide range of raw materials and specialty metals, including ferroalloys, rare earths, and minor metals.

US Magnesium’s plant in Utah closed down in September 2025

Jiangsu Mingmei Starts Mass Producing Components

According to Jiangsu Mingmei, on January 13th, a batch of precision magnesium thixomolded parts were loaded into containers after undergoing the final inspection process in the company's production workshop.

These products are about to be shipped to Shanghai Port and will ultimately be installed in the rear panel of the central control screen of a well-known international electric vehicle.

This is Jiangsu Mingmei's first order from a Taiwanese customer and represents a new milestone for its ambitions into becoming a global supplier of lightweight components.

A couple of months ago, Bole Intelligent Machinery delivered and installed several 850 ton and at least one 1,650 ton magnesium thixomolding machines to Jiangsu Mingmei’s factory.

Yizumi Sells 12 Die Casting Machines For Magnesium Parts Production

Yizumi has successfully won the bid for the die-casting machine and supporting equipment project of Wuchan Zhongda with a winning bid amount of 103.96 million yuan ($15 million).

The project involves a total of 12 die-casting production units, specifically including 8 sets of 1,600 ton, 2 sets of 2,000 ton and 2 sets of 2,50 ton die-casting production units.

The equipment will serve exclusively the production of magnesium alloy components to strengthen the position of the Wuchan Zhongda Group as a supplier of lightweight components.

Last Article: