Welcome to The Gigacasting Newsletter

New here? Subscribe

Toyota’s Gigacasting Ambitions Take Shape In China

The Lexus Shanghai plant’s Gigacasting shop completed the lifting of its first pillar.

In February 2025, Toyota announced that Lexus would establish a fully owned production facility in Shanghai dedicated to pure electric vehicles, with an initial annual capacity of 100,000 units and production slated to begin in 2027.

This facility will adopt Gigacasting technology and produce the Lexus LF-ZC, set for a 2026 launch and initial production in Japan.

This will be China's first wholly owned automotive plant by a foreign company, for both domestic and international sales, after Tesla established Giga Shanghai in 2019.

The facility will manufacture the new Lexus model using Toyota’s cutting edge technologies, including Gigacasting, self propelled production lines, and an unboxed assembly process to reduce factory investment and accelerate mass production setup.

Exclusive information from my database (industryarsenal.com/database) indicates that Toyota signed a deal for 9,000 ton die casting machines for the Lexus plant in Shanghai.

In addition to serving the Chinese market, 20% of the plant’s output will be exported to Europe and Southeast Asia.

Spanning 615,700 square meters, the plant’s development is divided into three phases:

• Stamping, die casting, body-in-white, painting, general assembly, and battery pack assembly.

• A dedicated battery workshop and an office building.

• Expansion of stamping and die casting, plus an additional battery workshop.

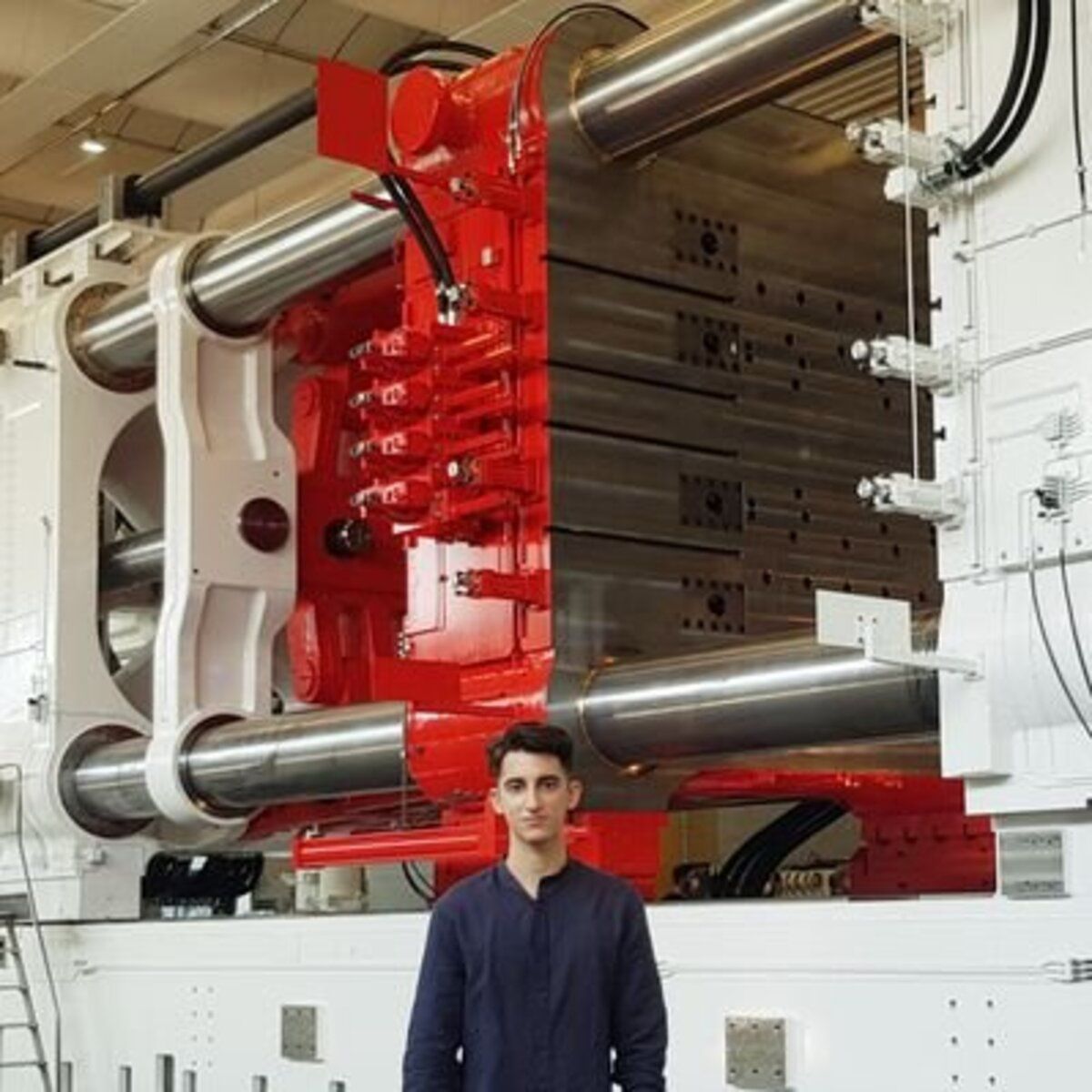

Toyota rear underbody Gigacasting pathfinder

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For inquiries, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

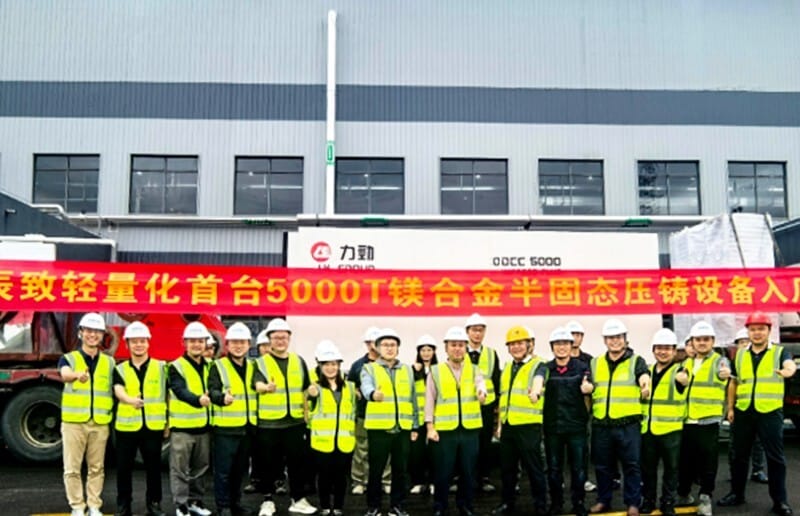

Changan Invests In Large Magnesium Thixomolding Technology

A subsidiary of Changan Automobile announced the official delivery of a 5,000 ton magnesium thixomolding and aluminum die casting machine.

This machine, produced by LK Machinery is equipped with a TPI (Thixotropic Piston Injection Technology) module.

The TPI module is mounted on the side of the clamping unit and can transform the 5,000 ton high pressure die casting machine into a magnesium thixomolding machine.

It means it can switch between magnesium and aluminum alloys components, enabling a flexible production.

This also marks the company's official entry into the production of magnesium alloy components to increase its lightweight products supply.

Die Casting For Mass Manufacturing Humanoid Robots

CITIC Dicastal has completed production testing on a humanoid robot leg skeleton component produced via high pressure die casting at its facility, with the initial batch of 20 mass produced units now shipped.

This could be the first or one of the first such products mass produced using HPDC for humanoid robots.

This milestone extends the company’s decades of automotive lightweight expertise into the structural domain of humanoid robotics.

The delivered components comprise four critical left and right-leg structural parts engineered specifically for dynamic locomotion.

Through targeted R&D led by the materials and research department, the parts meet aggressive lightweight targets while satisfying the extreme load and fatigue demands of complex motions, including walking, running, and load bearing.

CITIC Dicastal’s team replaced conventional forging/milling with HPDC to create a high efficiency, low cost production line.

The process boosts material yield to 85-95%, multiplying output rates several fold, and delivering dimensional precision that satisfies robotic assembly tolerances.

Looking ahead, the company is fast tracking magnesium alloy die casting processes. With a density just two thirds that of aluminum, magnesium offers transformative weight savings.

Tesla's Optimus robot has allegedly achieved a 42% weight reduction by using magnesium alloys according to leaks to the Chinese press earlier this year.

The reason I’m covering this topic is because if Humanoid Robots will deliver on their promises they will require billions of components never manufactured before in history.

In the next 5-20 years the demand for Humanoid Robots could unlock a massive market for foundries around the world.

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: