Welcome to The Gigacasting Newsletter

New here? Subscribe

First Look At World's Largest Magnesium Thixomolding Machine

In July, at the China Die Casting 2025, Haitian unveiled a 7,000 ton magnesium Thixomolding machine with production readiness scheduled for later this year.

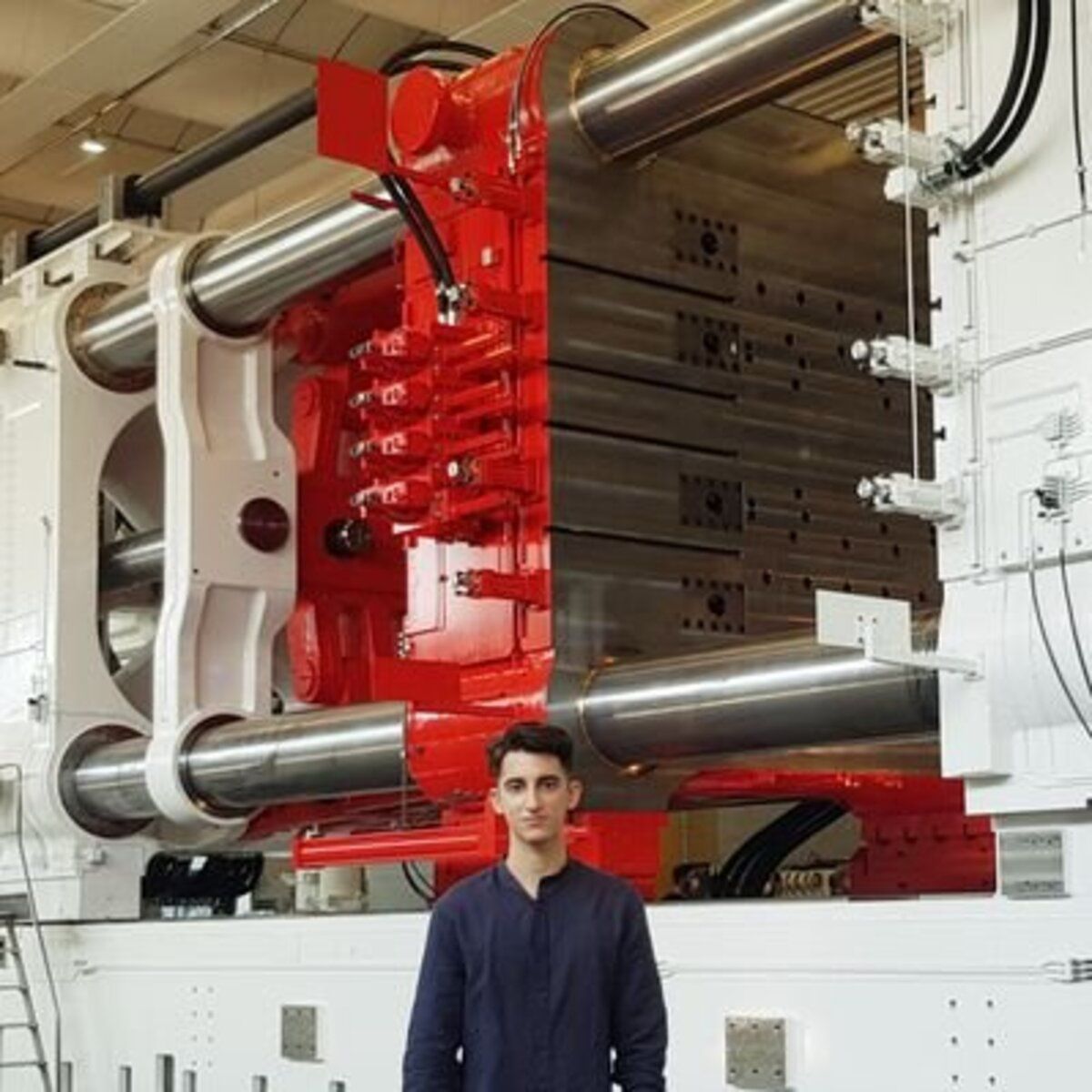

Haitian Metal now published on WeChat the first pictures of its HMG 7000, the world’s largest magnesium Thixomolding machine.

Haitian HMG 7000. Source: Haitian Metal WeChat

This machine is set to potentially achieve a record-breaking injection volume, though Haitian has yet to disclose further detailed specifications, I speculate that the injection weight could be likely above 35 kg.

To achieve this, Haitian will utilize a twin barrel configuration, like in plastic injection molding, two parallel barrels will generate the semi solid slurry and inject the material into the die.

This is very helpful to both increase the quantity of material you can process at once, shorten the flow length and keep the size of the screw smaller which can be a problem as the process scale up.

The drawback of the double injection system is the high cost, in fact the barrel and the screw are the most expensive part in a Thixomolding machine and doubling their number can be expensive.

Haitian released an illustrative example which shows the double injection can be performed in both synchronous and asynchronous configuration. The image below shows a tailgate on the left portion and a door on the right.

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

Dongfeng Starts The World Largest Die Casting Machine

The first 16,000 ton die casting machine at Dongfeng’s Wuhan plant has officially started trial production.

Hubei TV, a local Chinese newspaper, got access to the new factory in Wuhan where a 16,000 and a 10,000 ton die casting machines have been installed and are now producing test products.

LK Machinery’s Dreampress 16000 is making battery trays for fully electric vehicles. The mold cavity for this casting has a projected area of 4 square meters according to Hubei TV.

Some new details about the production process have been released. The production island has a cycle time of 135 seconds and Dongfeng aims for a scrap rate of less than 5%.

Dongfeng test battery tray extracted from the 16,000 ton machine . Source: Hubei TV

The project focuses on developing, manufacturing, and supplying ultra-large Gigacasting structural components for new energy vehicles, including front and rear underbodies, battery trays for hybrids and fully electric vehicles, and potentially C-D inner side panels for Dongfeng’s various brands.

Supported by a 226 million yuan investment ($31.2 million at the time of announcement), construction began in April 2024.

Upon completion, the plant will feature six die casting production lines, rolled out in two phases. China News toured the completed factory, sharing a video showcasing the facility’s readiness for trial production click here.

Once fully operational, the 16,000 ton and 10,000 ton machines are projected to produce a combined 200,000 units annually. When all the two phases are complete, the plant’s total capacity will reach 600,000 units per year.

Photo by Xie Jinxuan. Source: etp.dfmc.com.cn

Quick News

Tesla

On October 18, 2025, Tesla's Berlin team showcased its first fully automated Model Y rear underbody Gigacasting production line. This is the first of its kind for Tesla outside of Gigafactory Shanghai.

Unlike Tesla’s California, Texas, and Berlin factories, where Gigacastings were produced, stored, trimmed, stored again, and then machined, this new line seamlessly automates every step, from melting to final machining, streamlining production and enhancing efficiency. See the full video here.

Baowu Magnesium

On October 9, 2025, Baowu Magnesium announced via an investor interaction platform that it is the exclusive supplier of magnesium alloy product to Seres, the OEM behind Huawei’s AITO brand.

Current usage exceeds 20kg per vehicle. Looking ahead, the integration of large scale magnesium die cast components, including electric drive housings, rear underbody Gigacastings and door inner panels, is projected to increase magnesium usage to 50-100 kg per vehicle.

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Weekly Issue: