Welcome to The Gigacasting Newsletter

New here? Subscribe

New Tesla Model Y L

Tesla has introduced a new Model Y variant in China, a six-seat version with an extended wheelbase to provide more space for third-row passengers.

The Model Y L features a rear underbody Gigacasting, while the front retains a traditional body-in-white construction. This body architecture aligns with all Model Y vehicles produced across Tesla’s four global manufacturing facilities.

The Model Y L will be manufactured in Shanghai, Tesla’s highest-output factory. It remains unclear whether this specific model will be produced outside China in the near future.

Nonetheless, Tesla has announced plans to launch additional models this year, leveraging existing production lines to maximize output at its underutilized facilities.

The Austin and Berlin factories, each with a production capacity of 500,000 units annually, are Tesla’s most underused plants. I anticipate that Austin and Berlin may introduce new Model Y based variants with the same rear underbody Gigacasting architecture.

However, the front structure could differ to accommodate market-specific needs. For instance, a more compact Model Y tailored for Europe might require a shorter front end, justifying the use of a new redesigned front underbody Gigacasting.

Previously, Austin and Berlin produced Model Y variants with both front and rear Gigacastings, but these were discontinued due to scalability issues with the cells used in their structural battery packs.

If Tesla introduces a new model based on the Model 3 production line, I expect it will forgo underbody Gigacastings, consistent with the current Model 3’s body in white design.

six-seat Model Y L interior

New Possible Tesla Cybercab Sub-Assembly Spotted

Unidentified vehicle components were recently observed at Tesla’s Fremont factory in California.

As shown in the image on the left below, the structure appears to have a base with a shape that closely resembles, if not matches, the rear underbody Gigacasting (RUB) of the Tesla Cybercab (right image).

Note that this observation is based on low-resolution drone footage and has not been officially confirmed, but it invites some speculation. This could be the body in white of the Tesla Cybercab’s rear sub assembly.

According to Tesla’s unboxed manufacturing process, vehicle sections are constructed on parallel production lines. The front and rear sub assemblies, built around their respective Gigacasting underbodies, serve as the primary foundations for the body in white.

Once the body in white is complete (without paint in the Cybercab’s case), the sub assemblies are equipped with wiring, seats, and other components before being integrated into a single vehicle on the final assembly line.

The Tesla Cybercab is slated to begin production in 2026 using the unboxed manufacturing method, and its Gigacastings were previously spotted at Tesla’s Austin factory, you can read my analysis here.

Yizumi-DGS Partnership For Magnesium Thixomolding Improvement

Yizumi and DGS Group signed a strategic agreement to advance magnesium Thixomolding. The partnership combines Yizumi’s precision equipment with DGS’s expertise in mold design and die casting.

The goal is to tackle challenges in molding accuracy, production efficiency, and process stability, driving innovation and industrial upgrades in magnesium alloy applications.

The collaboration will operate with dedicated teams managing joint R&D efforts and a “DGS-Yizumi Semi-Solid Magnesium Alloy” initiative targeting global market expansion. Regular personnel exchanges, information sharing, and training will ensure smooth project execution.

DGS, a major automotive structural components supplier since 1925, serves major automakers like Volkswagen and BMW with advanced aluminum and magnesium alloy die casting.

Leapmotor And FAW Collaborate On Magnesium Products

FAW and Leapmotor held an in-depth discussion focusing on the technical attributes, application potential, and future collaboration opportunities for magnesium alloy products.

Leapmotor, a new Chinese electric vehicle manufacturer, has formed a specialized magnesium alloy team. FAW’s capabilities garnered strong interest from Leapmotor’s R&D team, who recognized that FAW could become a future key supplier for magnesium alloy components.

FAW Group is about to open a new factory equipped with 850 and 3,600 ton Thixomolding machines for the production of magnesium components. Read more here.

Quick News

Sinyuan ZM Plans To Raise Funds For Magnesium Thixomolding Expansion

Sinyuan ZM plans to issue convertible corporate bonds of up to 450 million Yuan ($62.8 million). The issuance has been approved by the company’s board and shareholders. It’s now pending review by the Shenzhen Stock Exchange and registration by the China Securities Regulatory Commission.

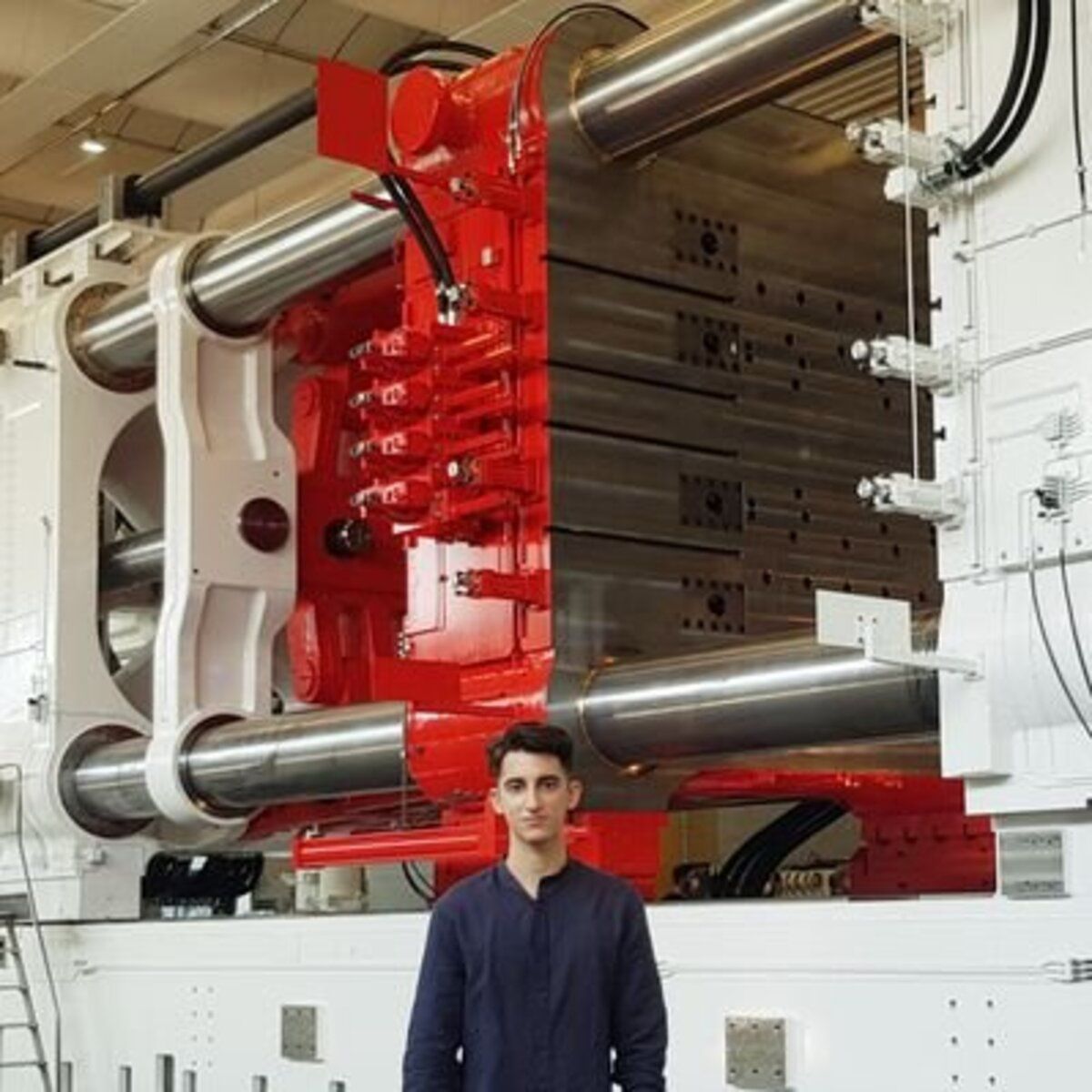

Sinyuan ZM will invest the money in the construction of a project to produce large, high-strength magnesium alloy Thixomolded parts for automotive applications. Recently Yizumi presented the world’s first Thixomolding “Giga” Machine (6,600 ton) which will be delivered to Sinyuan ZM.

Wencan Financials

In the first half of fiscal year 2025, Gigacasting supplier, Wencan reported revenue of 2.8 billion yuan ($390 million), a year-on-year decrease of 8.88%.

Net profit was 13 million yuan ($1.8 million), due to the decline of its European operations.

Wencan’s Chinese main business reached a net profit of 80 million yuan ($11.2 million), a year-on-year increase of 9.95%.

The body structural parts business, which includes Gigacastings, achieved 756 million yuan ($105.5 million) in revenue, a year-on-year increase of 13.43%.

The company has installed several die casting machines of 6,000, 7,000, 9,000 and 9,800 tons of clamping force and its customers include Nio, Li Auto and Seres (AITO).

If you are interested in tracking Wencan’s Gigacasting machines and its products, consider subscribing to the Industry Arsenal Database.

» 20% off « for early subscribers until September 12th

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: