Welcome to The Gigacasting Newsletter

New here? Subscribe

Ford Unveils Universal EV Production System

On August 11, 2025, Ford announced a $2 billion investment to transform its Louisville, Kentucky, assembly plant to produce affordable electric vehicles. This move aims to accelerate mass adoption of EVs and reverse the persistent losses in Ford’s EV division.

Ford’s new Universal EV Platform will enable the mass production of a diverse range of affordable vehicles. The platform’s first offering, a mid-size electric pickup truck, is set to launch in 2027, followed by crossover SUVs, ride-hailing vehicles, and other models.

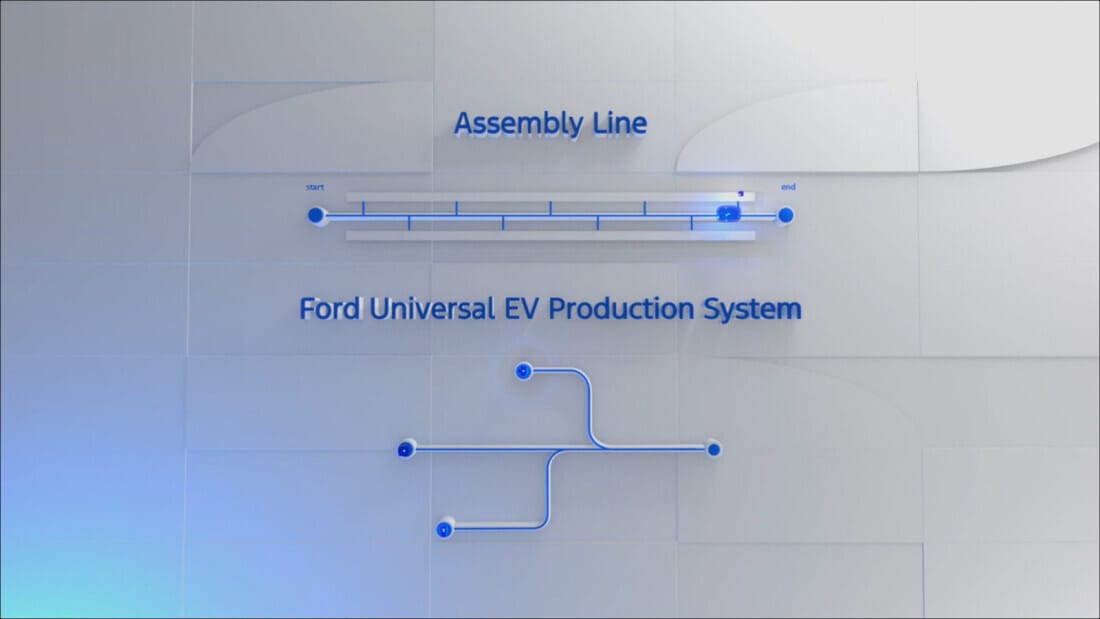

The Universal EV Platform, replaces the traditional single conveyor belt with a three branch assembly line; one for the front, one for the rear, and one for structural batteries, seats, center consoles, and carpets.

These components are then integrated into a complete vehicle, reducing workstations by 40% and increasing production speed by 15%.

The Universal EV Platform leverages Gigacastings, or as Ford refers to them “Unicasting”, to reduce the total number of parts by 75% compared to a conventional pick up truck body. Furthermore, with Ford’s Front and Rear Unicasting two thirds of welds and 50% of the fasteners will be eliminated.

Ford is the fourth automaker to announce the adoption of gigacastings combined with an “unboxed” assembly process. Tesla and Toyota revealed plans for similar assembly lines in 2023, while China’s GAC confirmed it will implement this production method for its next generation platform in 2026.

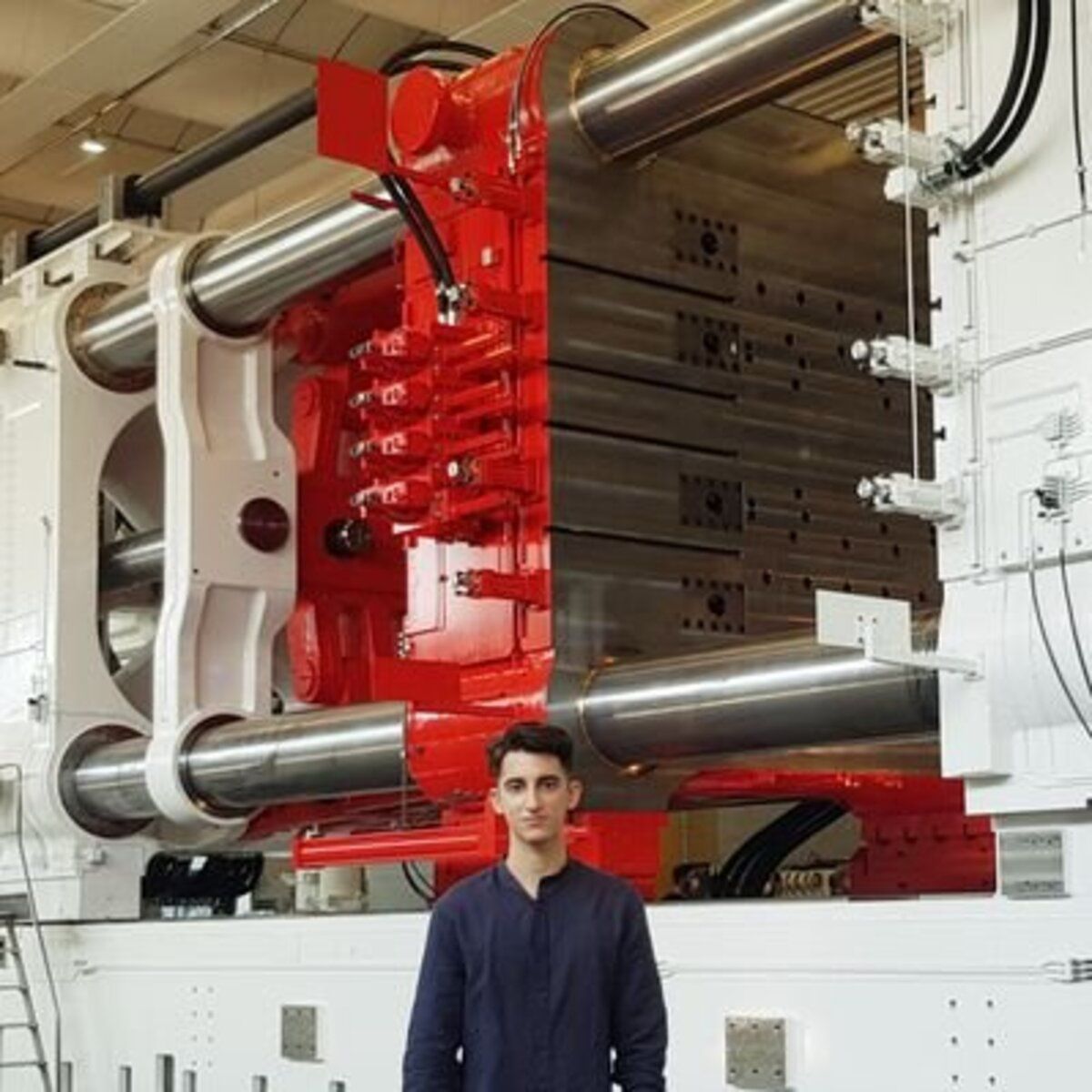

During the unveiling of its gigacasting technology, Ford presented a video that appears to depict the interior of Duoli’s foundry in China. This suggests Ford may be conducting trial production there.

Although the video does not show Ford’s Kentucky plant, I anticipate Ford will install 9,000 ton die casting machines in the upgraded Louisville facility.

Magnesium Thixomolding White Paper

Supreium Technology conducted an in depth research on magnesium alloy semi solid forming. Through surveys and collaborations across academia, equipment makers, OEMs, and die casters, they produced the industry's first Whitepaper on Magnesium Alloy Thixomolding Technology to provide theoretical and practical support for emerging trends.

1 Breakthrough in Lightweighting

Amid green manufacturing and carbon reduction, lightweighting is essential. Magnesium alloy, with density 1/4 of steel and 2/3 of aluminum, shines, especially as China holds 70% of global magnesium reserves and 91.6% of primary production capacity (keep in mind this whitepaper was made by a Chinese company).

Thixomolding leverages magnesium's thixotropic behavior in the semi solid state, enabling high quality, efficient forming of complex parts. Key advantages:

• Superior Flow and Low Defects: High fluidity for thin walls (≤1mm); lower temperature (100°C below die casting) reduce porosity and cracks; slower filling (3-4m/s vs. 6m/s) for stability; minimal oxidation due to enclosed processing.

• Enhanced Surface and Mechanical Properties: Due to the strong filling capacity of the semi-solid slurry, the surface roughness of the casting is improved compared to traditional die casting.

Shear-induced formation of uniform, fine spherulites (50-100μm) coupled with excellent fluidity and minimal porosity, boost tensile strength by 10% and elongation by 30-50%.

*thixomolding 1 and 2 was done at different temperatures of the slurry which impacts solid fraction

• Efficiency: Since there is no thick biscuit and the runner is thinner, you can achieve 70-85% material utilization; lower energy; 20-30% shorter cycles.

*thixomolding 1 and 2 was done at different temperatures of the slurry which impacts solid fraction

2 Market Opportunities

China leads global New Energy Vehicle (NEV) production: 9.59M units in 2023, rising to 13.17M in 2024 (+38%). This drives lightweight material demand, where magnesium excels in strength, electromagnetic interference shielding and damping.

Auto sector consumes 70% of the magnesium (385k tons globally) produced annually and the NEVs in China use ~10kg of magnesium per car vs. 5kg in ICE vehicles. The total demand for magnesium could grow from 570k tons in 2024 to 1.35M tons in 2027.

Applications evolve: Traditional applications such as instrument panel backs and center console brackets continue to see significant growth.

Large structural components such as shock towers, battery pack housings, and motor casings are emerging as new growth areas.

With the widespread adoption of new machines with a capacity of >4,000 tons of clamping force, trial production of ultra large structural components such as door inner panels and rear hatch inner panels has already begun.

Economically, Thixomolding boosts competitiveness: SAIC Motor's second generation EV motor housing, successfully overcame the technical bottleneck of a porosity of less than 3%. This has resulted in a 20% improvement in mechanical properties, a leap in the yield rate from 78% to 95%, and an 18% reduction in overall costs.

All of this was achieved while reducing the weight by 30%.

BYD has completed trial production and testing for ultra large housings weighing 8kg for a single unit and over 15kg for a three-piece set. Xiaomi and Geely are accelerating the implementation of this technology, while Li Auto, NIO, and Hongqi (FAW Group) have completed engineering verification.

3 Challenges to Scale-Up

Despite promise, hurdles remain:

• Process: The injection system's screw-barrel system must simultaneously handle both slurry melting and stirring, as well as high pressure injection.

This complex structure forces its components to withstand the combined impact of 600°C metal slurry and nearly 100 MPa of pressure, resulting in a wear rate more than three times that of an injection molding machine.

• Materials: In order to ensure the uniform suspension of solid particles to achieve thixotropic properties, you need to maintain a semi-solid temperature range of approximately 100°.

Currently, the new corrosion resistant and high strength magnesium alloys under development in the industry achieve significant performance improvements through micro alloying with the addition of rare earths and/or calcium elements.

• Costs: Thixomolding machines are 2-3 times more expensive than die casting machines.

Conclusion

Magnesium Thixomolding offers a compelling solution for lightweighting, with vast growth potential in electric vehicles, consumer electronics, and humanoid robots.

Enhanced by digital advancements such as CAE multi-physics simulation and artificial intelligence, coupled with rapid development in large scale equipment, this technology is poised to unlock significant potential.

It is set to capture a multi-billion-yuan market while positioning China's high end manufacturing industry as a global leader in competitive markets.

FAW Magnesium Thixomolding Factory

As previously reported in March of this year, FAW announced the construction of a magnesium alloy production base in the Changchun Automobile Economic and Technological Development Zone.

This facility, which leverages magnesium Thixomolding as its primary production processes, is now entering the final stages of trial production. The base features Thixomolding production lines that integrates R&D, trial production, and quality control, with an estimated annual output value of 80 million yuan ($11.1 million).

We now know that the production facility is equipped with an 850 ton magnesium thixomolding machine capable of producing components for instrument panel brackets, steering wheel frames, and more.

While a 3,600 ton machine can produce door inner panels, cross car beams (CCB) and other structural components for vehicles.

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: