Welcome to The Gigacasting Newsletter

New here? Subscribe

Apply the promo code "Gigacasting-25" to get 25 CHF off on the Rheocasting Masterclass

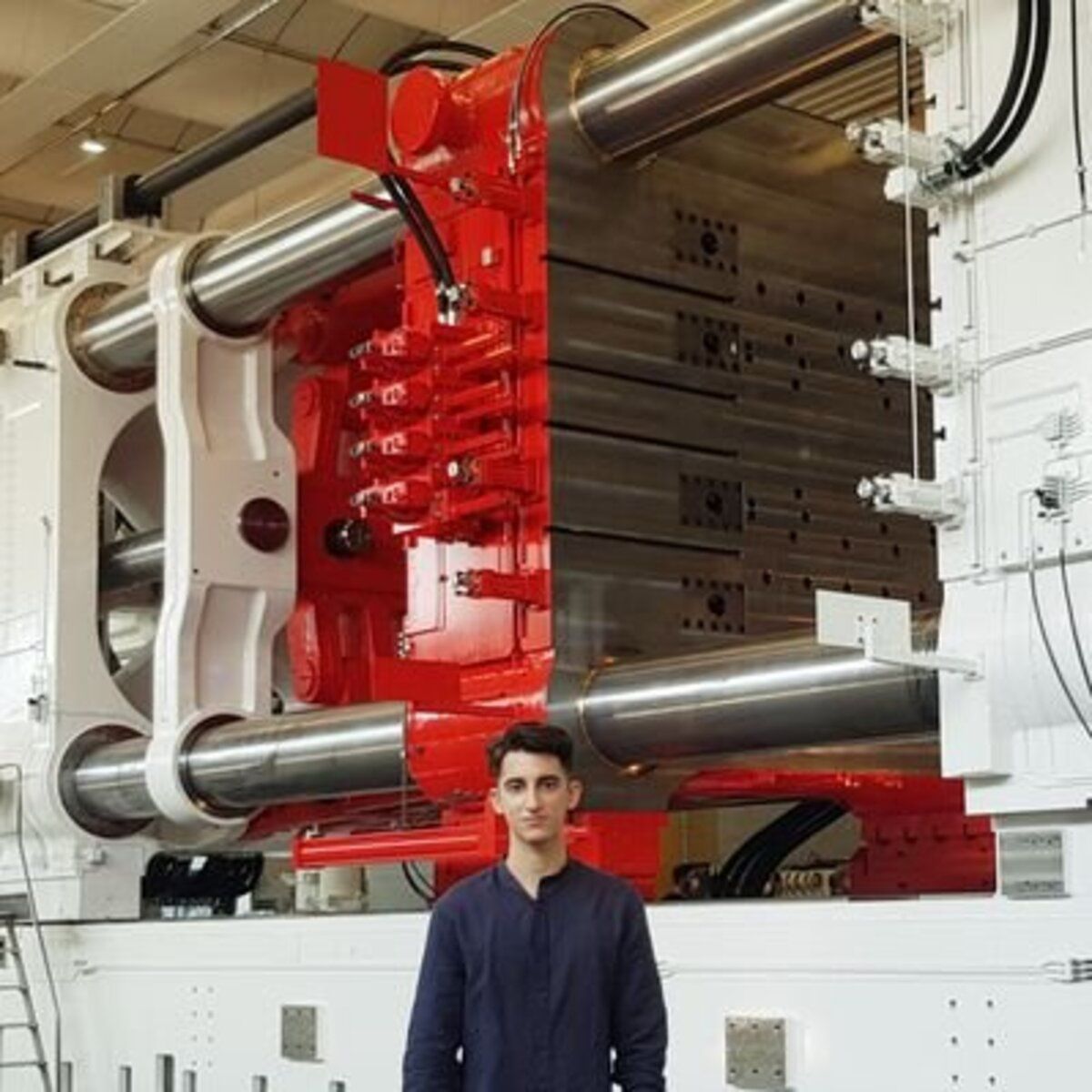

Yizumi Kicks Off The Gigacasting Era For Magnesium Thixomolding

On July 16, 2025, Yizumi successfully delivered its UN6600MGII magnesium Thixomolding machine to Sinyuan ZM, marking the start of the “Gigacasting” era for the magnesium Thixomolding technology.

Traditional magnesium die casting methods suffer from low material utilization and yields, protective gas environmental/cost issues, short mold life and safety issues during the casting process especially when the material is molten, hindering scalability.

In contrast, Thixomolding ensures that the semi-molten material remains fully isolated from environmental oxygen, as melting occurs entirely within the sealed barrel.

Moreover, even in the event of an incident, the volume of semi-molten material is significantly lower than in conventional die-casting furnaces, where several tons of material are maintained in a fully liquid state simultaneously, greatly enhancing overall safety.

Yizumi’s new 6,600 ton machine increases the shot weight from its previous max of 15kg to 38kg. This increase is both achieved through doubling the number of injection units but also by increasing the diameter size and power of each injection unit.

The twin-screw design enables simultaneous melting of magnesium alloy feedstock, delivering double the melting capacity of a single-barrel system. Although this solution can be more expensive.

Yizumi also claims to have successfully increased its injection pressure capacity to ensure the internal density of large parts and minimize shrinkage porosity problems common in conventional thixomolding processes for thick walled components.

Additionally, the machine supports multi point hot runner integration, slashing casting waste by 30%, shortening flow distances by over 500 mm, and achieving more uniform pressure and temperature distribution in the mold cavity resulting in denser, higher quality castings overall.

a message from our sponsor

The Gigacasting Newsletter readers get 25 CHF off using code "Gigacasting-25"!

Rheocasting is a cutting-edge die casting process that leverages a semi-solid aluminium slurry to deliver high-quality parts with reduced defects like porosity and cold flows while doubling the life of your tools.

For Gigacasting enthusiasts, Rheocasting is a game-changer, tackling key large-scale casting challenges. Its thixotropic slurry flows long distances at low speeds, ensuring consistent high properties while slashing the required clamping force and capex on these massive presses, dies, and equipment.

Dive deeper with the Rheocasting Masterclass from Casting-Campus GmbH. For more information, visit rheocasting.info

Haitian Will Present A 7,000T Magnesium Thixomolding Machine By Year End

Haitian unveiled its groundbreaking 7,000 ton magnesium Thixomolding machine at CHINA DIECASTING 2025, with production readiness slated for later this year.

Similar to Yizumi’s model, it incorporates a twin-screw injection system designed to substantially boost the volume of magnesium injected into the die.

This machine is set to potentially achieve a record-breaking injection volume, though Haitian has yet to disclose further detailed specifications.

The past two years have seen an explosive growth in larger Thixomolding machines. Milestones include a 3,000 ton unit with double injection capabilities, Haitian's 3,600 ton model, Bole's 4,000 ton machine, and TPI's solution for converting existing aluminum die casting islands into Thixomolding machines.

Recent announcements from key players underscore this momentum: Haitian's 7,000 ton machine, Yizumi's newly delivered 6,600 ton with injection units enabling up to 38 kg shot weights, and Bole's forthcoming 6,000 ton model featuring a 30 kg shot weight, scheduled for installation later this year, alongside plans for even bigger developments.

As a result, shot weights have escalated dramatically, from just 2.5 kg a few years ago to over 38 kg today, a more than 15-fold increase in under five years.

This swift advancement heralds a trasformative shift in magnesium Thixomolding technology, paving the way for expansive applications in automotive, electric vehicles, aerospace, and beyond.

Xiaomi Published A Patent For Magnesium Gigacastings

Chinese tech giant Xiaomi recently published a patented about a structural magnesium die casting alloy and its preparation method, designed for lightweight, safety critical applications. The alloy achieves high bending performance with minimal rare earth content and no heat treatment in order to contain costs.

The journey begins with a fundamental understanding of why magnesium alloys fail under stress. Magnesium's hexagonal close-packed crystal structure restricts its ability to deform at room temperature, limiting slip systems and making it prone to cracking during collisions.

Through microstructural analysis using scanning electron microscopy (SEM), the patent highlights key failure modes: cracks often initiate at coarse second phases, like needle-shaped or long rod-like structures (Al11RE3), where stress concentrates at sharp tips.

In contrast, finer, more uniform alpha-magnesium (α-Mg) grains help slow crack propagation, improving overall toughness. Building on this, the inventors scrutinized conventional magnesium alloys as well as those enhanced with Rare Earth (RE) elements.

Traditional alloys suffer from drawbacks such as low elongation or insufficient strength, poor castability, or the need for high RE content, which drives up costs. Some prior patents rely on heat treatments like T6, but these are impractical for large automotive parts due to deformation risks.

A critical highlight from the patent: tensile elongation doesn't directly translate to bending performance. While elongation measures uniform stretching, bending involves complex stress states more akin to real-world collisions.

Thus, the inventors set ambitious targets: bending resistance of at least 50° equivalent angle on a 2mm-thick 30×60mm samples (VDA 238-100 test), all without heat treatment.

To meet these goals, the inventors chose the AM-series (Mg-Al-Mn) as a base. The alloy was found to best suit Xiaomi’s mechanical, casting, and cost requirements, when featuring the following elemental composition (in weight %):

• 4.5-6.5 Aluminum (Al)

• 0.15-0.50 Manganese (Mn)

• 0.01-1.2 Yttrium (Y)

• 0.03-0.50 Calcium (Ca)

• <0.20 of Zinc (Zn)

• <0.01 of Fe+Ni+Cu

• <0.05 of impurities

• remaining Magnesium (Mg)

• 0.2-1.8 Rare Earths (RE); Lanthanum (La) and Cerium (Ce).

• 0.5 ≤ RE+Y ≤ 2.0

• 1 ≤ RE/Y ≤ 12

Tested alloys composition. First; Examples 1-9. Followed by; Comparative Examples 1-8.

Iron, nickel, and copper were capped at ≤0.01 wt% total, and zinc at ≤0.20 wt%, to minimize corrosion and crack initiation sites.

Aluminum was dialed in at 4.5–6.5 wt%, providing castability without forming excessive coarse Mg17Al12 phases that could embrittle the alloy.

Grain refinement was key to enhancing ductility. Calcium was added for this purpose, reducing average α-Mg grain size to ≤12 μm. This finer structure creates more barriers to crack growth, boosting bending performance.

Yttrium offers solid solution strengthening and forms high-melting Al2Y particles that act as nucleation sites, refining both the matrix and any RE-induced phases.

Theory alone isn't enough; the patent emphasizes hands-on validation. Casting performance was assessed with an S-shaped flow mold (about 3mm thick), aiming for a fill length over 3.5m without defects like hot cracks, rated "OK" for success or "NOK" for failure.

Mechanical properties of the tested alloy compositions. First; Examples 1-9. Followed by; Comparative Examples 1-8.

The patent outlines nine successful examples and eight comparative cases. Examples 1-9 consistently demonstrate a bending angle exceeding 50° and elongation above 12%, with the highest yield strength of 142 MPa and tensile strength of 268 MPa.

The most significant microstructure comparison was done between Example 3 (Fig 1) and Comparative Example 7 (Fig 2).

(Fig 1) Example 3

(Fig 2) Comparative Example 7

Example 3 reveals small, well dispersed second-phase particles with an average α-Mg matrix grain size of approximately 10 μm.

In contrast, Comparative Example 7, where yttrium is absent, results in a lack of Y-RE coordination. This leads to coarser second-phase structures, including prominent long, rod-shaped phases. Comparing Fig 1 with Fig 2, the addition of yttrium in Example 3 enhances Y-RE coordination, effectively refining the α-Mg matrix and Al11RE3 phase sizes.

How does Xiaomi’s magnesium alloy compare with other Aluminum Gigacasting Alloys?

The tensile strength of this alloy is competitive with the top aluminum Gigacasting alloys disclosed in published patents. However, its yield strength falls in the mid to lower range compared to other aluminum Gigacasting patents.

The alloy's elongation stands out as potentially the highest reported for a Gigacasting alloy. Comparable bending test data for other Gigacasting alloys used in the automotive industry is not readily available.

Xiaomi Mg patent | Al Gigacasting range | |

|---|---|---|

Yield Strength (MPa) | 118 - 142 | 110 - 175 |

Tensile Strength (MPa) | 236 - 268 | 180 - 270 |

Elongation (%) | 12.1 - 16.7 | 7 - 12 |

For the full patent click here

More about Xiaomi click here

More about Magnesium Gigacasting application click here

New Tesla Model Y Variant

Tesla has officially unveiled the Model Y L, a new variant of its popular electric SUV designed specifically for the Chinese market. This model features an extended wheelbase, making the vehicle longer overall, particularly at the rear, to comfortably accommodate six seats.

Production has already begun at Tesla's Shanghai Gigafactory, with sales slated to start in autumn 2025.

The structural modifications, especially the lengthened rear section, may necessitate updates to the vehicle's rear underbody Gigacasting to maintain structural integrity and manufacturing efficiency.

At present, specific technical details on these changes and their precise effects on the underbody remain unclear.

US Magnesium Production

The US Government Accountability Office published a bulletin on critical minerals production from desalination waste brines.

For the full report click here

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Write to [email protected] to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!

Last Article: