Welcome to The Gigacasting Newsletter

New here? Subscribe for weekly updates

At the IAA Mobility 2025 event in Munich, held September 9-14, 2025, Volkswagen held a Technology Day presentation where they announced the adoption of Gigacasting for several upcoming entry-level EVs.

The initial strategy includes integrating a large aluminum casted battery tray, or better, the frame of the tray. This technology will first be adopted by the brand new VW ID. Polo, Cupra Raval, and Škoda Epiq, as well as the VW ID. Cross (production version not unveiled yet).

Dr. Marc Adam, during the session, discussed the future of large castings, emphasizing benefits like reduced production time, lower complexity, and cost savings, while noting possible plans for new facilities equipped with 8,400 ton die casting machines focused on integration, productivity, and efficiency.

The presentation also provided an outlook on expanding VW's casting strategy, positioning it as a milestone for high-volume EV platforms.

Volkswagen has not taken a final decision on integrating front and rear underbody Gigacastings, but it was made clear that should they decide to follow the “Tesla route” in the future, then they will require larger machines, such as 8,400 tons which were mentioned during the presentation.

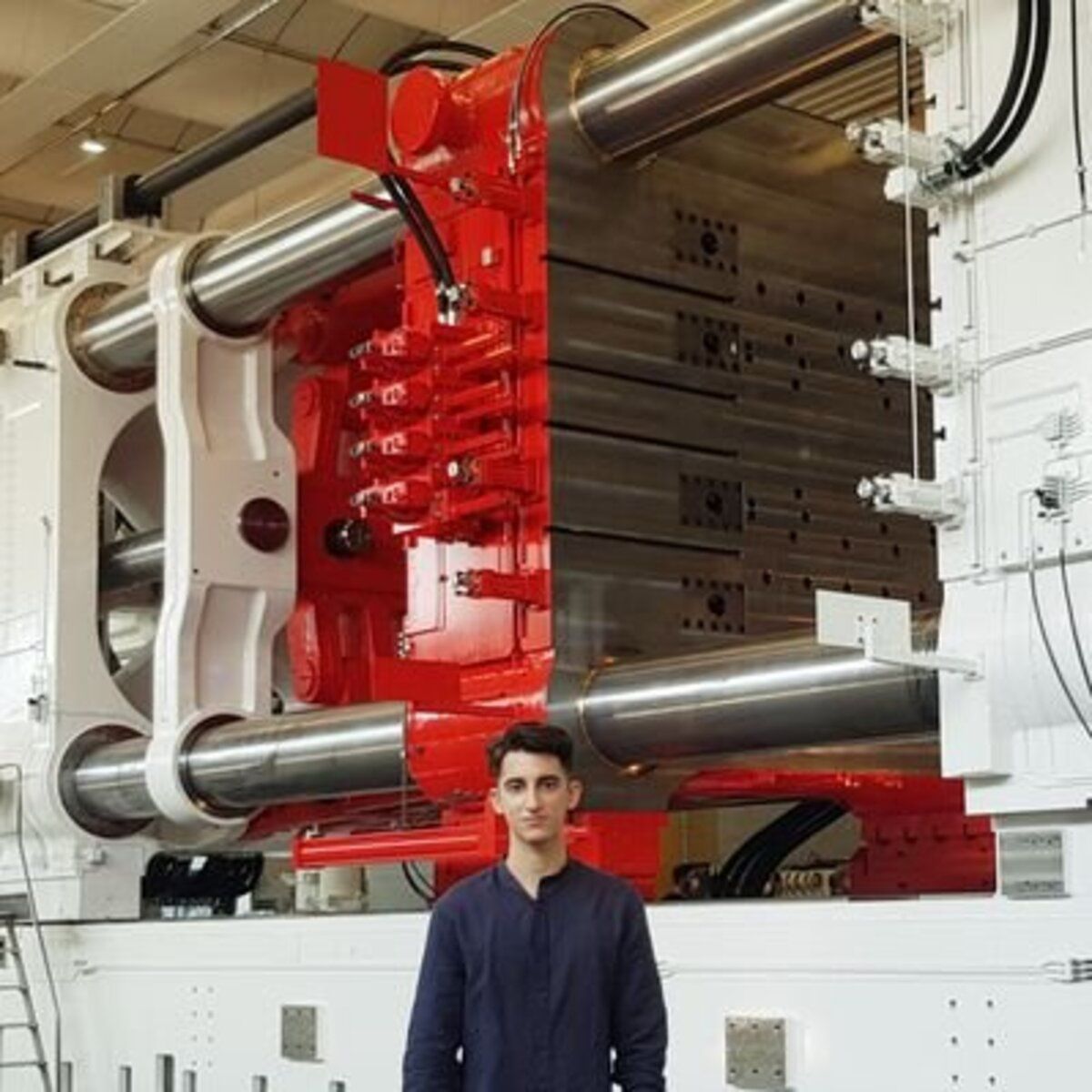

Credit: Martin Lagler

Smaller front and rear Gigacastings made with 4,400 ton machines in Kassel, Germany were showed at the event (see them below) but these serve as pathfinders, key for R&D efforts and will not be present in VW future models.

Credit: Martin Lagler

The Battery Frame

The battery frame presented will be Volkswagen’s first Gigacasting application in its vehicles. These include The Electric Urban Car Family lineup, ID. Polo, ID. Cross Concept, Cupra Raval and Skoda Epiq.

It is the German Group’s most complex casting yet, 1.7 m long, 1.15 m wide, which replaces 123 individual parts and helps reduce weight by 10%, to 62 kg.

Further details describe a 120 seconds cycle time and the use of 3 plate die technology. The cost reduction is 15%.

This battery frame is a very interesting solution and it differentiate itself from other Gigacast battery trays which we have seen in the past.

Credit: Volkswagen

Honda is also adopting a die casted battery tray, but it includes the entire floor which is a very large surface that increases the clamping force needed to lock the die in place during the die casting process.

This translated to the need for larger machines, as we have seen, Honda uses 6,100 ton machines in Ohio to produce just half of the battery tray, while in China, they make the entire tray in one shot utilizing a 12,000 ton die casting machine.

Instead Volkswagen focuses on the frame of the battery tray, avoiding the larger flat surfaces but still integrates a lot of components. It appears that a lot of connection points for internal components, such as battery cells/modules, management and cooling system should be present in the frame.

Another key aspect of this design choice is weight. Volkswagen will likely fill the voids in the floor with other components that will likely be much lighter and thinner than what you can achieve with die casting.

Credit: Volkswagen

This is beneficial because the battery frame is produced using only a 4,400 ton die casting machine, as we have seen in Kassel, earlier this year.

While official VW press releases from IAA focused more on AI, batteries, bidirectional charging, and design, the Gigacasting details emerged through attendee reports and social media, with no public video or full transcript readily available from VW.

The Gigacasting Database

📊 The Gigacasting Database is a powerful tool for industry professionals to keep track of what’s going on in the Gigacasting industry

Our comprehensive Database is a collection of all the Gigacasting machines installed worldwide, including exclusive information to give you an edge in staying ahead of the game in the Gigacasting industry

It includes High Pressure Die Casting machines from 6,000 tons and above, including large magnesium Thixomolding machines

The Gigacasting Database includes a full list of all the vehicles using this technology and all the relevant information about them

View the full list of contents: industryarsenal.com/upgrade

For more information, please write an email to [email protected]

Each subscription helps me avoid having to search for sponsors, contributes to the independence of my newsletter and to higher quality reporting, Thank you!

🎯 Reach the heart of the die casting industry with The Gigacasting Newsletter, the world’s most targeted newsletter and website for die casting professionals.

🌐 With thousands of engaged subscribers and high-impact ad placements, your business can connect directly with decision-makers and innovators in the field.

📩 Visit IndustryArsenal.com/collab to discover how The Gigacasting Newsletter can elevate your brand. Secure your spot today!