Welcome to The Gigacasting Newsletter

New here? Subscribe for weekly updates

In April 2025, two new Gigacastings never seen before have been spotted outside Tesla’s factory in Austin, Texas. One new rear underbody (RUB) and one new front underbody (FUB). These castings were for Tesla’s robotaxi dedicated vehicle, the Cybercab.

Left: RUB (over 400 spotted). Right: FUB. Credit: https://x.com/JoeTegtmeyer

Rear Gigacasting

1) No wheel arches

The casting is streamlined to minimize material use, with one key difference from other Tesla castings: the exclusion of the innermost flat wheel arch section.

Integrating wheel arch covers into the rear casting is the most cost effective approach, as it reduces the number of parts and manufacturing time and steps. However, this design presents challenges.

The wheel arches, being large, flat surfaces, must be thin to save weight, which makes them prone to deformation and complicates the flow of the material and cooling.

Excluding the wheel arches from the casting simplifies the process, logistics and reduces weight by replacing a casting wall thicker than 2mm with a thinner stamped sheet. However, this introduces additional manufacturing steps and components.

Left: RUB with wheel arches. Right: Tesla Cybercab RUB. Credit: https://x.com/JoeTegtmeyer

2) Weight Estimate

Similar designs in Chinese vehicles, which exclude wheel arches, typically result in castings weighing around 40 kg.

Given the Cybercab’s smaller size and reduced flat surface area, its casting could weigh well below 40 kg, a lot lighter than the Model Y’s RUB casting, which is approximately 60 kg.

3) Die design

The side of the casting is completely flat or at least for the vast majority of its length and surely drastically flatter than compare to the Model Ys.

This suggests that the die design doesn’t require the typical lateral slide cores seen on every underbody Gigacasting die design.

This could significantly reduce costs and complexity while maintaining structural integrity, aligning with the Cybercab’s optimized design goals.

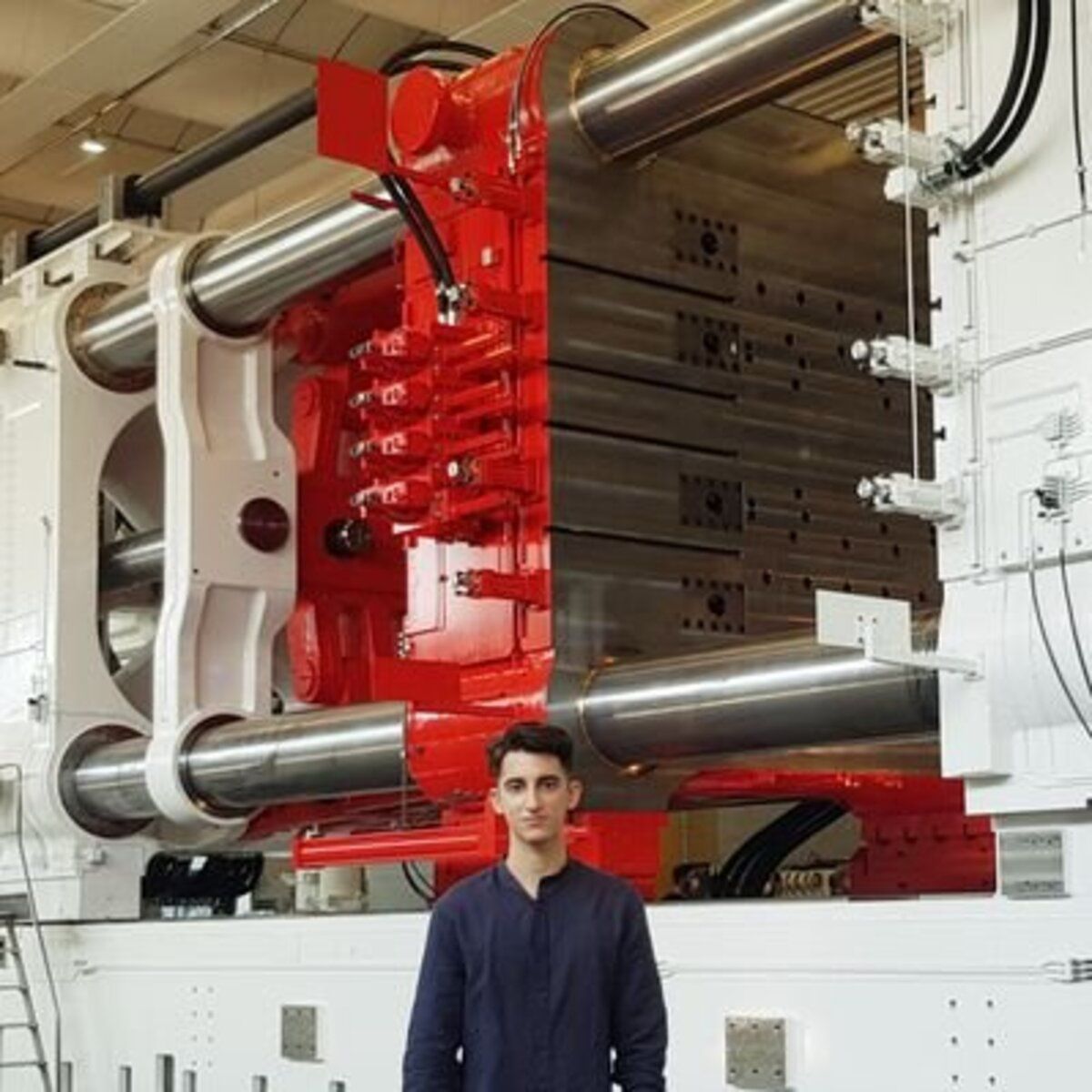

Tesla Model Y RUB die

4) Impact on Logistics

The compact design excluding wheel arches, enables at least 10 castings to be stored per rack, doubling the capacity of the Model Y RUB casting (5 per rack) and exceeding the Cybertruck RUB (4 per rack), despite all racks having nearly identical volumes.

This is significant because storage management has been a challenge at Tesla’s factories, where building inventory is essential due to the lengthy die swapping process and subsequent downtime for the massive casting machines.

Credit: https://x.com/JoeTegtmeyer

Front Gigacasting

The front underbody (FUB) Gigacastings closely resemble the Cybertruck’s castings in shape, featuring similar ribs and progressive crash-absorption structures, though they use a significantly different ingate system.

However, they are noticeably smaller, appearing more compact than the Cybertruck’s castings when observed alongside workers on the factory floor.

Why do the front castings include wheel arches?

The shock towers are a critical component of the front casting design.

Not integrating them into the main casting, compared to the RUB, would require adding way too many parts in subsequent manufacturing steps, undermining the efficiency of using a Gigacasting for the front.

That said, the large wheel arches in the front casting certainly pose challenges, as evidenced by the extensive rib structures used to enhance the structural integrity of these large, flat areas.

Below: untrimmed Cybertruck FUB. Up: untrimmed Cybercab FUB. Credit: https://x.com/JoeTegtmeyer

Unboxed Manufacturing Process + More castings reduce the number of total BiW parts by 60%

From the video released during Tesla’s shareholder meeting, we can see the main front sub-assembly (built on the Front Gigacasting) being lowered down to mate to the other components, such as the steer by wire, heat management system, suspensions, etc...

The rear sub-assembly of the Tesla Cybercab appears to be a hybrid body design which incorporates two (at least) large aluminum die casted components and stamped panels.

Notably, the large underbody Gigacasting forms the base of the entire structure while the newly spotted C-shaped casting forms the upper frame of the rear sub-assembly.

These design choices is what contributes the most to the 60% part count reduction of the Tesla Cybercab compared to the Tesla Model Y.

Important: Note that the 60% reduction in parts is not just for the underbody section or the rear sub-assembly, it’s for the entire Body-in-White!

Credit: https://x.com/JoeTegtmeyer

💡 Tesla's "Unboxed" process is a manufacturing technique for electric vehicles that replaces the traditional linear assembly line, where vehicles move sequentially through stations for part additions, with a modular approach.

Instead, key sections of the car (such as the front, rear, battery pack, and side panels) are assembled in parallel sub-lines, mostly around the Gigacastings, as independent modules then integrated in a final assembly stage.

Why is this important?

This method aims to reduce production costs, shrink factory footprints by 40%, and accelerate output. Elon Musk also claimed the cycle time for this production line will be under 10 seconds.

Furthermore by coating BiW section of the vehicles in smaller sub-assemblies and painting external panels before assembling the vehicle, you can reduce the Paint Shop size by 70% according to Caresoft Global.

The Tesla Cybercab is even more extreme when it comes to the paint shop because its Gigacastings will not be coated and the body panels don’t require painting.

Toyota, GAC and Ford announced their own versions of the "Unboxed Process" while other European OEMs are also studying similar solutions.